Image source: Popular Mechanics, August 1963.

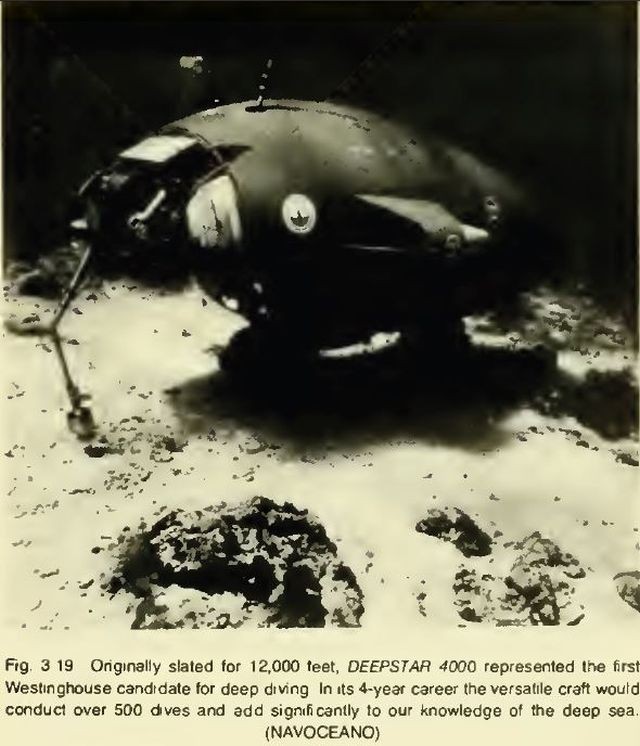

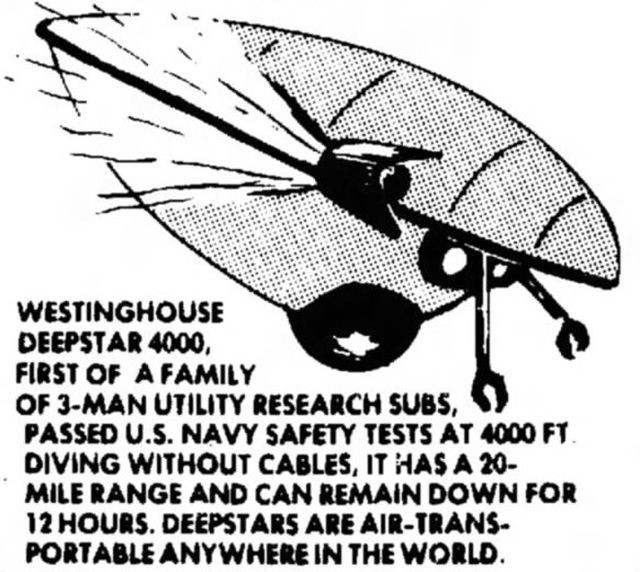

1962 – Deepstar 4000 Diving Saucer – Jacques-Yves Cousteau / Westinghouse launched in 1965.

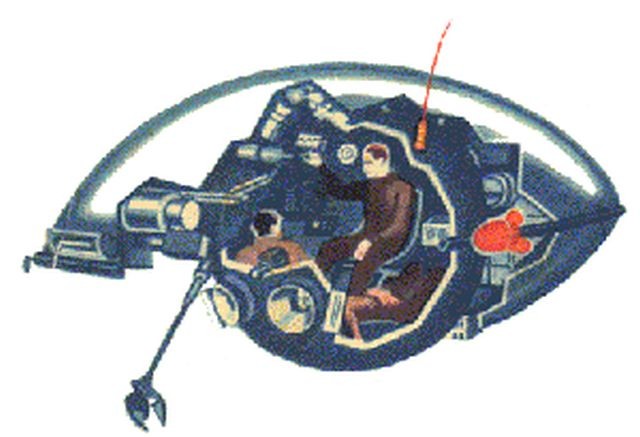

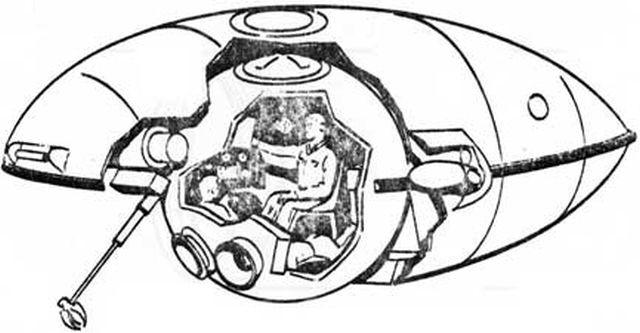

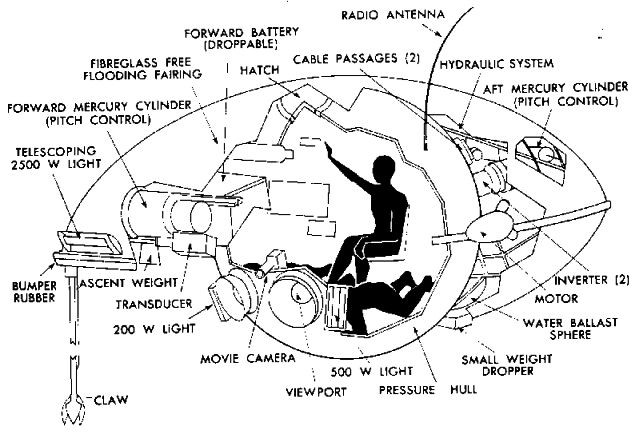

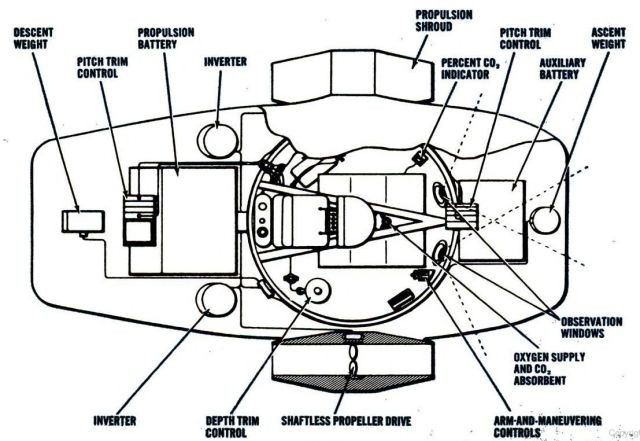

26 Jun 1962-NEW YORK: William E. Knox, president of Westinghouse International, demonstrates the flexibility of a remote control arm, part of a unique deep-sea vehicle at a 6/26(/62) press conference. The new self-propelled vehicle, to be named "Deepstar," which will be built by Westinghouse Electric, will give a three man crew the maneuverability needed to explore the "last frontier on earth." A cutaway drawing of the vehicle appears in the background.

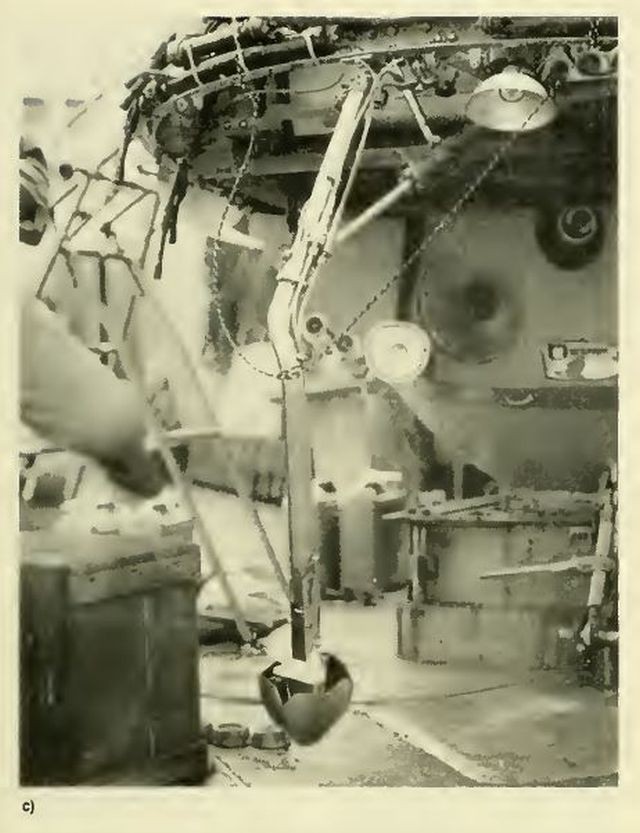

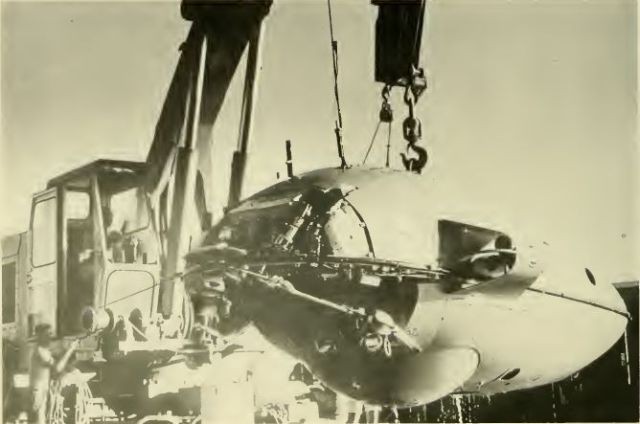

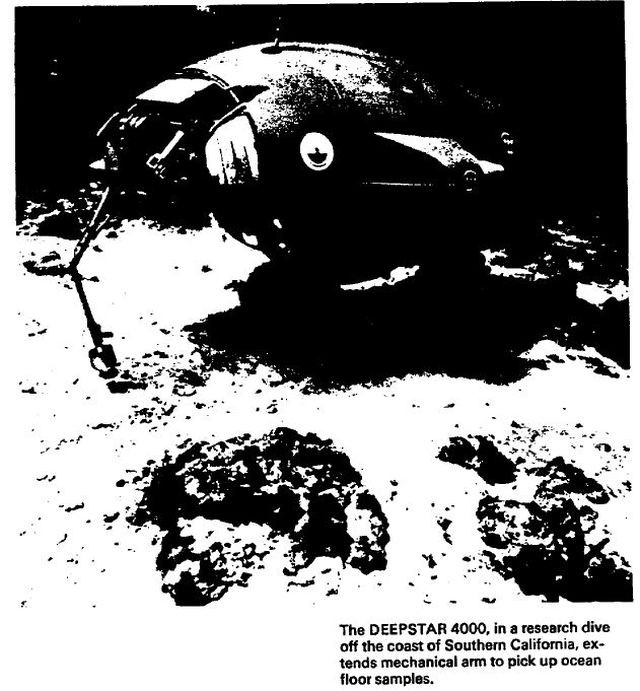

Manipulator arm is folded away.

See 7:06 into video clip.

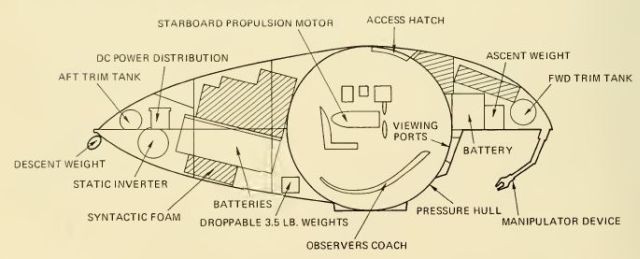

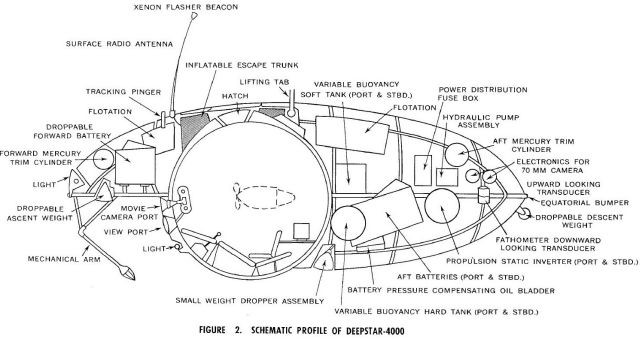

Source: Undersea Studies With The Deep Research Vehicle Deepstar-4000, March 1969

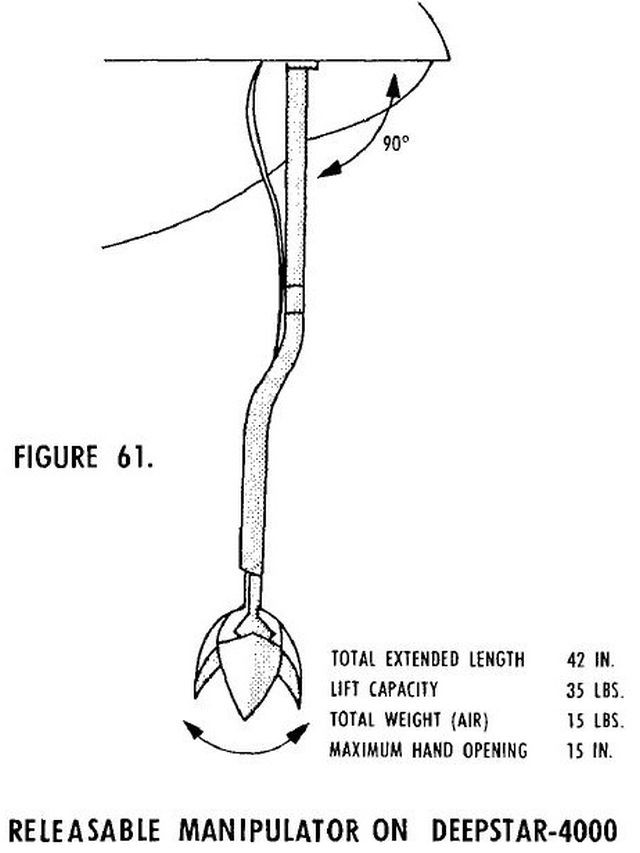

Manipulator and Bottom Sampling Devices

A single mechanical arm (Figure 61) with only three degrees of freedom can be installed in about three hours on DEEPSTAR. This arm weighs 15 pounds, has a maximum reach of 42 inches and can lift about 35 pounds. In most cases, due to the limited dexterity of the arm, the vehicle is manoeuvred in conjunction with the arm to obtain a sample. A basket, which can extend from the port side of the vehicle, is used to store samples. At the outward end of the arm is an orange peel sampler. Experience showed that the sampler's fingers were often bent and forced out of alignment. A more rugged arm with increased dexterity would be far more effective and a variety of hands or end samplers is also desirable.

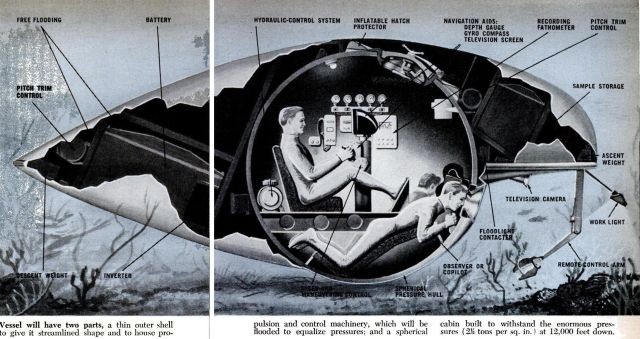

Image source and for in-depth article see Popular Science, October 1962.

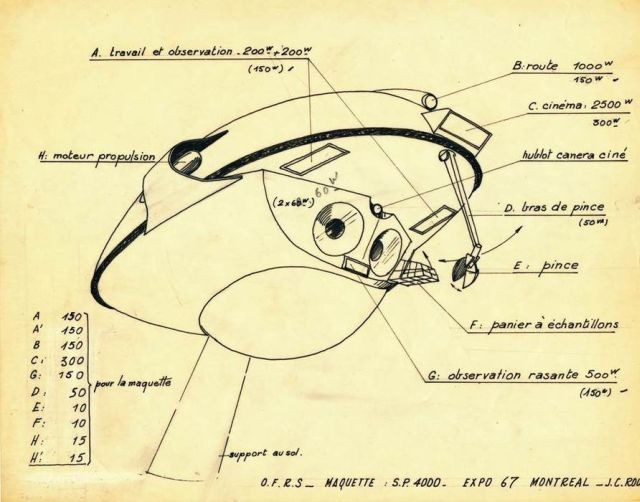

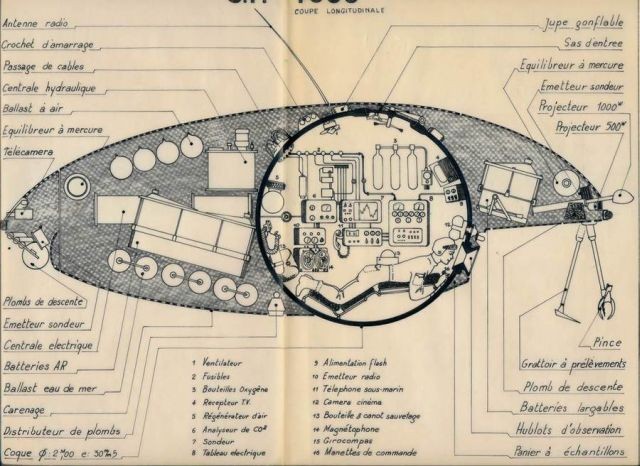

Initially the S.P. 4000, it was built in collaboration with Westinghouse and became the D.S. 4000, or Deepstar 4000.

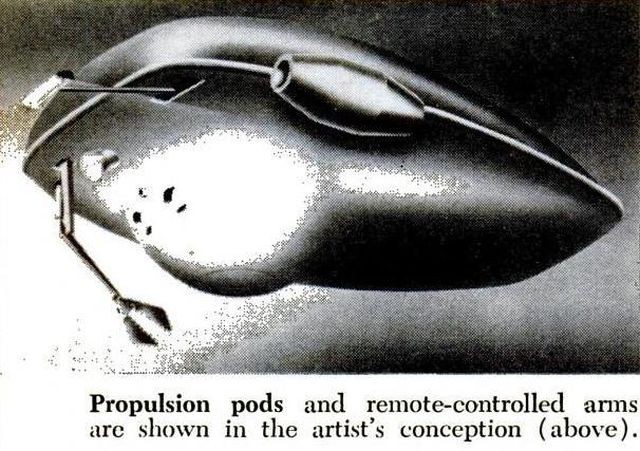

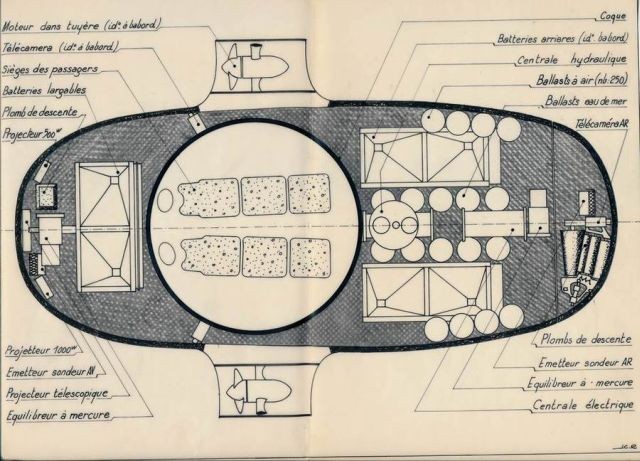

Cousteau's futuristic designs were done by his long time friend, Jean Charles Roux. The above illustration being for the S.P. 4000 maquette in Expo 67, Montreal.

Expo '67, Montreal.

Image source: here

Source: Tyrone Daily Herald, Jul 14, 1967.

Related Patents:

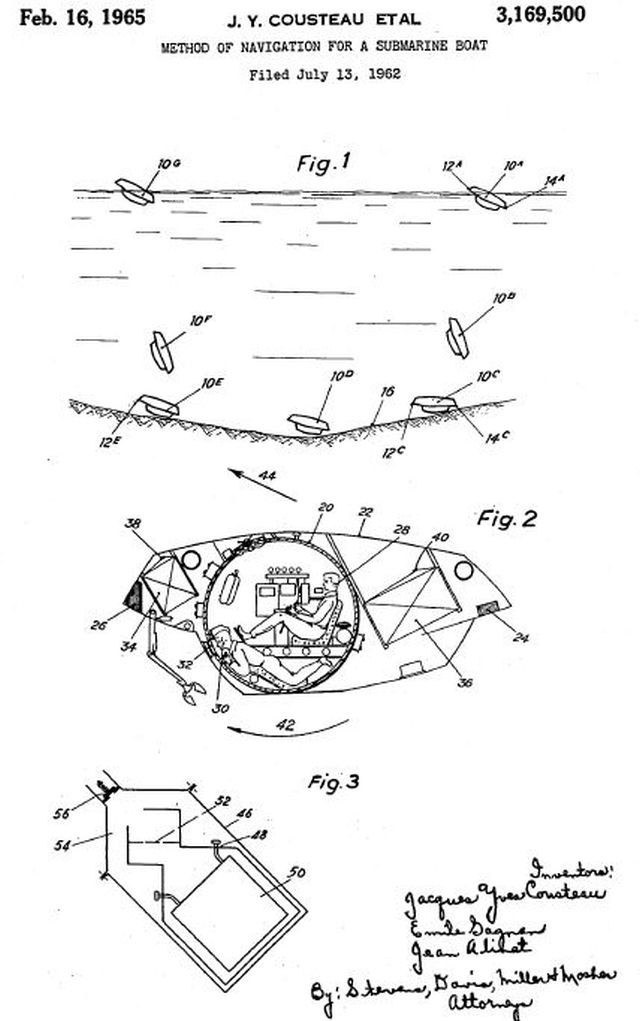

Method of navigation for a submarine boat

This patent not so much describes Deepstar 4000 per se, but includes description on manoeuvring the vehicle that also effect the positioning of the manipulator arm. Further, the drawings includes a diagram of Deepstar 4000.

Publication number US3169500 A

Publication type Grant

Publication date Feb 16, 1965

Filing date Jul 13, 1962

Priority date Jul 21, 1961

Inventors Gagnan Emile, Alinat Jean, Cousteau Jacques Yves

Original Assignee Spirotechnique

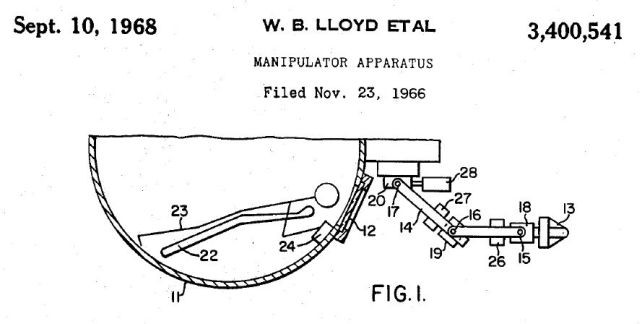

Publication number US3400541 A

Publication type Grant

Publication date Sep 10, 1968

Filing date Nov 23, 1966

Priority date Nov 23, 1966

Also published as DE1531286A1

Inventors Lloyd Wayne B, Schlissler Earl R

Original Assignee Westinghouse Electric Corp

Description

ABSTRACT OF THE DISCLOSURE

Manipulator apparatus for use on undersea vehicles. An exterior-mounted multi-joint manipulator arm has a respective hydraulic actuator and electro-hydraulic flow control valve at each arm joint. Common hydraulic supply and return lines connect the several control valve to a sea-ambient pressure-compensated hydraulic supply-return system. Current regulating means at an operators station provides for operation of the control valves, and means are included for equalizing all hydraulic volumes within the system at sea-ambient-compensated pressures during de-activation of the apparatus.

Powered manipulators mounted on the exterior of the hull of space and undersea vehicles are employed for grasping and manipulating objects at the exterior under the control of an operator inside who has visual contact with the manipulator and the object to be grasped or manipulated. A typical manipulator to which the present invention relates is generally a simplified mechanical simulation of a human arm and includes the grasping means, mechanical arm sections, and pivot joints, corresponding grossly to wrist, elbow and shoulder joints. Power actuators, commonly hydraulic rotary actuators, are affiliated with the several pivot joints of the manipulator and the operator inside the hull in observance of such manipulator through such as a window in the hull, controls operation of the several rotary actuators to dictate movements of the manipulator to obtain operation of the mechanical hand. The ease and rapidity with which the task of controlling operation of the manipulator is accomplished is greatly affected by the type of control system provided for the several actuators embodied in such manipulator.

Presently, the most common control means for each of the several actuators is a three-position control valve with upon, the operator must initiate the rate of motion by operating the proper control valve in the proper direction, visually monitor the effect the valve operation is having on manipulator position and then consciously terminate the movement by suitable valve operation. With employment of such on-otf valve control, the result has been a fixed rate of speed of operation of a particular actuator, hence, particular rate of joint movement. The problem arising with fixed rate control is that a compromise must be reached between high speed operation of a given actuator (open for rapid slewing through wide angles) and low speed for fine control near the object to be grasped. As a result of this compromise, both rapid slewing and fine control are sacrificed in such conventional fixed-rate manipulator systems. This results in lost time in doing work with such a manipulator and increases the possibility of damage to the object to be grasped, or of damage to the manipulator.

Such conventional manipulators as employ on-off control valves mount such valves at a fixed location relative to the hull of the craft and remote from the actuators at the arms of the manipulator, and require an undue multiplicity of hydraulic lines of considerable length extending between the control valves and the actuators on the manipulator joints; two separate hydraulic lines being required for operation of each of the actuators so controlled by on-off selector valves. Such long lines tend to establish low resonant frequency conditions which introduce lags in response of the actuators to dictates of the control valves as well as pose a problem of suitable protection for all such lines during operation.

The on-off selector valves are usually of the poppet valve type which tends to introduce random and erratic high creep rates of the mnaipulator joints due to leak-by at the poppet valves which tend to become slightly unseated by particles of dirt which can accumulate on the seat.

Because of employment of such multiplicity of separate hydraulic lines between respective on-off selector valve devices and the actuators they control, these lines and actuator chambers to which they are connected tend to establish entrapped volumes of hydraulic fluid in lap position of the valves which can experience severe pressure changes at their exterior during ascent or descent of an undersea vehicle, which can cause implosion or explosion of hydraulic components as a result thereof.

In view of the foregoing remarks it is the prime object of the present invention to eliminate the above problems, either separately or collectively, i.e., to provide for adjusting the rate of operation of the manipulator joint actuators, to reduce the number of hydraulic lines employed for operation of the several actuators, to overcome the problem of implosion or explosion of hydraulic components during ascent or descent to and from great depths, to employ a control valve system which greatly reduces the tendency for leak-by within the valve responsible for creep of the actuators and manipulator joints, and to provide a simplification in construction and an increase in reliability and dexterity in performance of the system.

In general, the above object is obtained in the present invention by the provision of a manipulator apparatus which, in addition to the usual actuators mounted on the manipulator arm joints, also includes respective variable rate electro-hydraulic servo valves mounted directly on the manipulator arm sections. The servo valves have only two hydraulic lines common to all of such valves and which extend therefrom to a hydraulic power supply system located externally of the hull of the craft on which the manipulator is mounted; each servo valve being constructed to minimize leakage between the hydraulic lines to the actuator as well as to provide for establishing interconnection between all hydraulic ports, passages, lines, etc., in the actuator system, including the hydraulic power supply, whereby internal hydraulic pressure becomes equalized with the environmental pressure of the system by way of ambient-pressure-compensated hydraulic supply system. Operators control means disposed within the hull of the craft provides for electrical control of operation of the variable-rate electro-hydraulic servo valves by way of electrical lines passing through the hull of such craft.

Manipulator apparatus

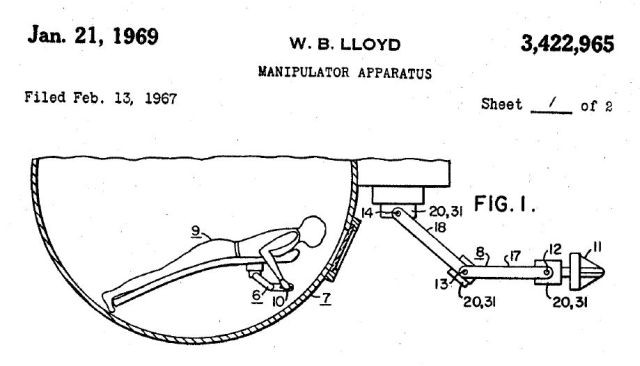

Publication number US3422965 A

Publication type Grant

Publication date Jan 21, 1969

Filing date Feb 13, 1967

Priority date Feb 13, 1967

Inventors Lloyd Wayne B

Original Assignee Westinghouse Electric Corp

Description

ABSTRACT OF THE DISCLOSURE A master-slave manipulator apparatus useful on undersea vehicles in which a master arm inside the hull is actuable by an operator to effect corresponding movement of an exterior slave arm, without requiring control feedback from the slave arm, comprising multiple-pivot slave,

and master arms with hydraulic rotary actuators on the slave arm joints, an open-loop control system including electro-hydraulic flow-control servo valve devices on the slave arm for controlling rate of supply of hydraulic fluid to the actuators respectively, and means for producing respective control signals for the servo valves on the slave arm according to the angular velocity and acceleration between relatively movable parts of the master arm at each of its joints, the angular positions of such master arm parts with respect to a common reference, and the relationship between such conditions which affect gravity and inertia torque loads on the respective actuators of the slave arm.

The present invention relates to manipulator apparatus.

Background of the invention 1) The invention relates to hydraulically-operated master-slave manipulator arm apparatus suited for use on undersea vehicles.

(2) Previous attempts have been made to use the master-slave method of control to improve manipulator agility. At least one of these, having both position and force feedback, is almost unbelievably agile, but its master arms are bulky, the system is very complex and the mean time before failure tends to be short.

The conventional approach to master-slave control is by use of a closed position servo loop through use of a position pick-off mounted on each joint of the slave arm and used in conjunction with a companion pickoff on the control arm. This type of position slaving has the disadvantages of position pickotfs operating in the hostile environment and of many additional wires (from the pickoffs) passing through the pressure hull. Another disadvantage given for prior art master-slave manipulators with position feed-back is the snap-in effect, which is the alignment transient which can occur when the system is first turned on with an initial misalignment between the position of the master and slave arms.

In the case of undersea applications, the disadvantages mentioned above, along with that of higher cost, have largely prevented the use of master-slave manipulators.

Summary In view of the foregoing remarks, the present invention provides a master-slave manipulator apparatus which preserves the agility and maneuverability of this type of apparatus, but which overcomes the above objections to previous forms of such type by use of an open-loop control system which takes into consideration relationships at the master arm which affect gravity and inertia torque conditions of the slave arm.

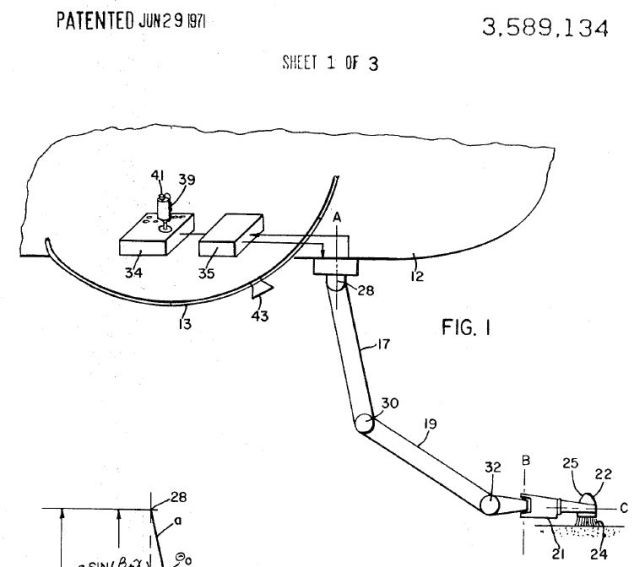

Publication number US3589134 A

Publication type Grant

Publication date Jun 29, 1971

Filing date Oct 30, 1969

Priority date Oct 30, 1969

Inventors Hackmann Robert L, Hunt Donald W

Original Assignee Westinghouse Electric Corp

MANIPULATOR APPARATUS BACKGROUND OF THE INVENTION

1. Field of the Invention Manipulator arm assemblies and controls therefor.

2. Description of the Prior Art

Mechanical arms, sometimes referred to as manipulators, are very often used when a particular environment is too hostile or dangerous for a man's direct participation. The manipulators provide an extension of the human arm capability in addition to motions and capabilities not performable by a human.

A typical manipulator includes two or three pivotal arm sections the last of which carries a tool, cleaning brush, or some other terminal device such as a gripping mechanism, for performing a certain task. The terminal device is visually observed by an operator by means of direct observation or by a television system. In moving the terminal device to a desired location the operator uses a model of the manipulator served to the actual manipulator, or a puppet arrangement where control cables attached to the operators arm move the manipulator in a corresponding manner to the arm; these types of controls can be very fatiguing to the operator and in addition where response times are relatively slow the operator must make a move and then wait to see the response of the manipulator assembly and thereafter take any necessary corrective action. This move and wait technique greatly extends the time required to perform a given task. In a manipulator having three pivots and three arm sections if it is desired to move the terminal device along a line it is necessary for the operator to command at least three different pivot actuators. An under or over command requires corrective action of one or more pivots and the relatively simple task of moving in a straight line becomes an extremely complicated procedure.

It is therefore a primary object of the present invention to provide a control system for a manipulator apparatus which relieves the operator of cumbersome and detailed manual control for various desired line movements.

SUMMARY OF THE INVENTION A control system for manipulator assembly is provided which includes a plurality of actuators which in response to an input signal pivotally move the arm sections of the manipulator relative to one another. One of the actuators is commanded to move one of the arm sections and a positional orientation of the commanded arm section is sensed and the remaining actuators are provided with input signals to command them as a function of the positional orientation of the first arm section.

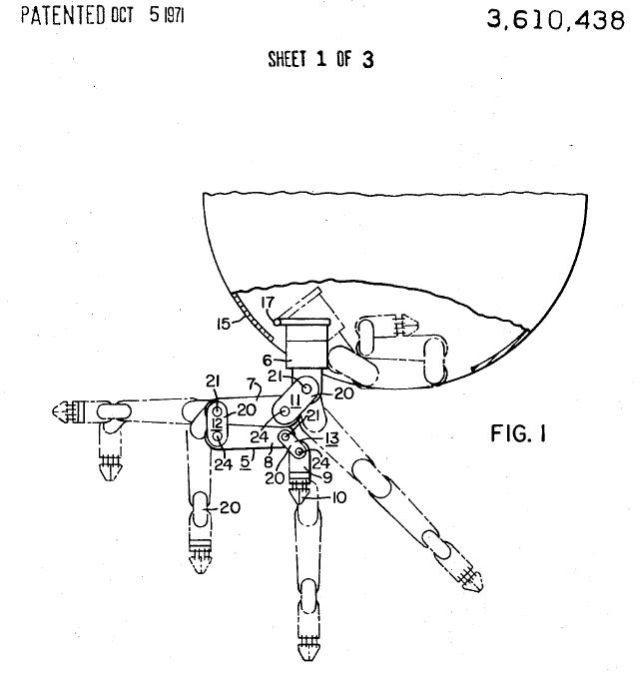

Manipulator arm

Publication number US3610438 A

Publication type Grant

Publication date Oct 5, 1971

Filing date Mar 16, 1970

Priority date Mar 16, 1970

Also published as DE2112066A1

Inventors Opdahl Everett W

Original Assignee Westinghouse Electric Corp

Description

ABSTRACT: A manipulator arm is exemplified which employs externally at its joint a pair of parallel actuator links extending longitudinally between pivotal connections on adjacent rounded arm section ends that are coupled together for rolling motion of one of such ends on the other. Rotary actuation of the links about the pivotal connection on one arm section causes a greater rotary movement of the other section about such connection. Control and/or actuator lines extend longitudinally inside the arm; interconnected at the arm section joints via flexible sections snaked between the actuating links for constant length at all angular joint positions.

MANIPULATOR ARM

BACKGROUND OF THE INVENTION

1. Field of the Invention

Manipulator arms suited for use on undersea vehicles.

2. Description of the Prior Art

It is common practice in manipulator arm constructions for undersea use to employ a fork fitting or offset hinge at the arm section joints. In either case, it is difficult to pass control and/or actuator lines through the joints. If the lines are run externally, they are susceptible to damage or snagging unless shrouded, which is difficult to achieve.

In order to obtain joint motions in excess of 90deg, rotary type hydraulic actuators have been employed, which are located directly at the pivot axes of the joints. This type of actuator installation also inhibits the passage of control and/or actuator lines therethrough.

Arm joint constructions which permit one arm section to fold back against another, heretofore have been difficult if not impossible to attain. A result has been that the degree of compaction of the arms during stowage has been undesirably limited, hence the arm storage demanded has been greater than desirable.

In certain existing arm joint constructions, actuators become exposed and/or protrude when the arm assumes a folded position. This makes them susceptible to damage when stowed externally of the vehicle and/or increases stowage volume requirements.

Still further, certain existing arm joint constructions result in inefficient use of their structural components, hence tend to contribute to increased weight due to larger size required to compensate for the inefficiency.

For light duty manipulators, it is desirable to locate the actuators at the shoulder arm section rather than at the joint being driven, since this reduces the parasitic weight which the arm must lift during its operation. It is difficult to provide for such remote actuation of the joints in previous arm constructions.

SUMMARY OF THE INVENTION The present invention, in providing a manipulator arm construction in which the ends of arm sections at the joints are caused to roll about the ends of adjacent arm sections by angular movement of one end of pairs of actuator links disposed at opposite sides of the exterior of such arm, opportunity is afforded for readily overcoming the limitations of the prior art set forth in the preceding description of such prior art.

The externally situated actuator links, being pivotally connected at one end to one arm section and at its other end to the adjacent arm section affords longitudinal space between the two pivot locations to accommodate extension of S-shaped flexible control and/or actuator line sections that transfers itself by bending progressively onto one or the other arm section end without changing length during angular movement at the arm joints in one direction or the other. With the actuator links being disposed along the exterior of the arms at the joints, disposition of such lines within their protective confines is afforded.

By virtue of the rolling motion of one arm section end over the end of the adjacent arm section, angulation of the one section relative to the other to the extent of 180deg for foldback is readily obtainable, and by virtue of obtaining such rolling motion by the turning of one end of the respective actuator link pair to obtain a multiplication of the resultant arm section movement, efficient use of rotary input motion is obtained.

By virtue of longitudinal separation between the input axis about which the rotary input motion occurs and the axis on which the actuated arm section turns, considerable choice of input motion actuator is afforded, including a hydraulic rotary actuator coaxial with such input axis, a local reciprocating piston actuator crank-arm-connected at such input axis, a remote actuator connected via cables in the arm to crank arms at such input axis, etc.

See Cousteau's earlier SP-350 here.

See other early Underwater Robots here.