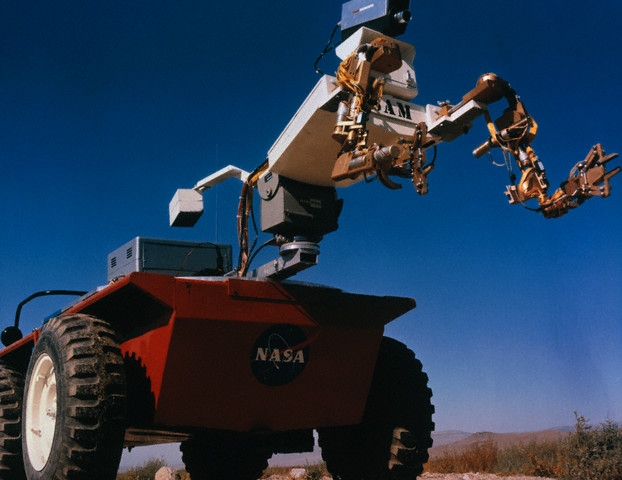

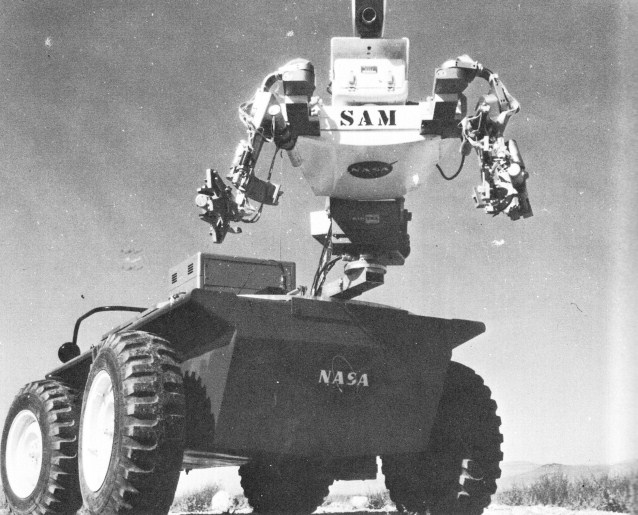

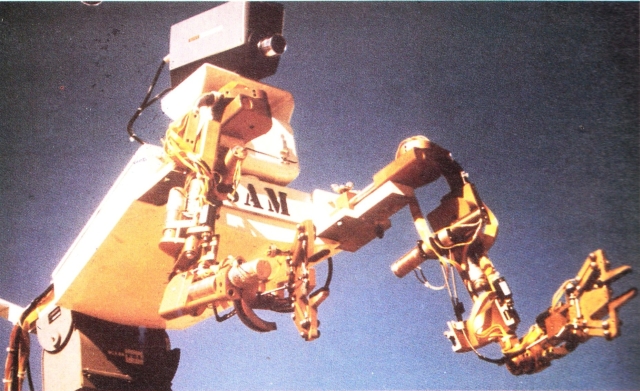

SAM, a mobile manipulator, mimics the movements of an operator stationed at a far-distant control center.

The Self-propelled Anthropomorphic Manipulator (SAM) that wears NASA logos was developed under Edwin Johnsen's direction in 1969 by the now defunct Space Nuclear Propulsion division of the U.S. Atomic Energy Commission. Johnsen is credited with introducing the popular term "teleoperator" in 1966 to describe a servo controlled manipulator that is not directly connected to the operator's twin manipulator.

RISE OF THE ROBOTS – George Sullivan 1971

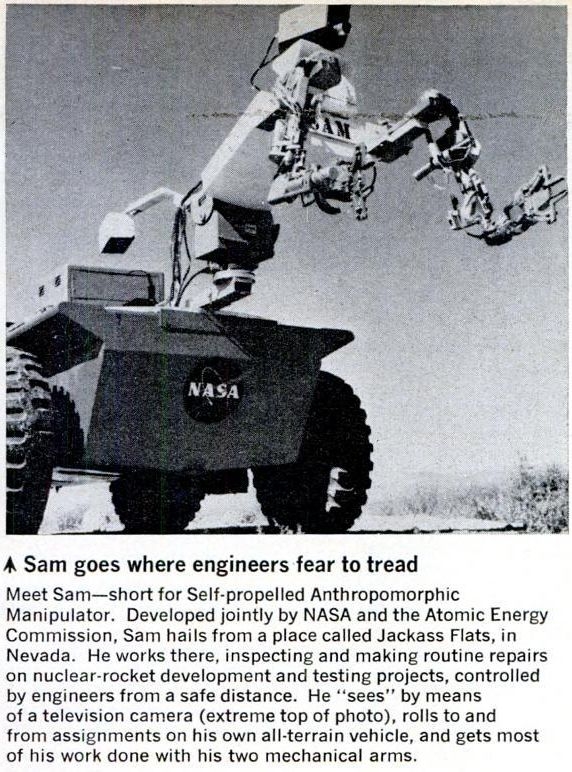

Government scientists representing the Space Nuclear Propulsion Office of the Atomic Energy Commission have taken the basic operational principles of the mobile manipulator and added an extra—long-distance control. The machine they've developed is one of the most exciting advances in teleoperator technology in recent years.

Nicknamed "SAM" ( for Self-propelled Anthropomorphic Manipulator), the unit is composed of two distinct parts. A machine portion features steel arms and hands, very similar to the arms and hands used in handling radioactive materials inside hot cells. These arms and hands, however, are mounted on a steel boom which moves up and down and in a circular pattern to give a wide range of operation. The boom, in turn, is mounted on an open, four-wheeled vehicle about the size of an Army jeep. This "torso" portion of the unit is topped with a small television camera. Its "eye" peers down at whatever the hands grasp. The second portion of the unit is the control station, the command post for the human operator. The control station and the mobile manipulator are linked by a coaxial cable, the same type of insulated conducting tube that is used to transmit television signals from a studio to viewers' homes. The two parts of the system can also be linked by radio control.

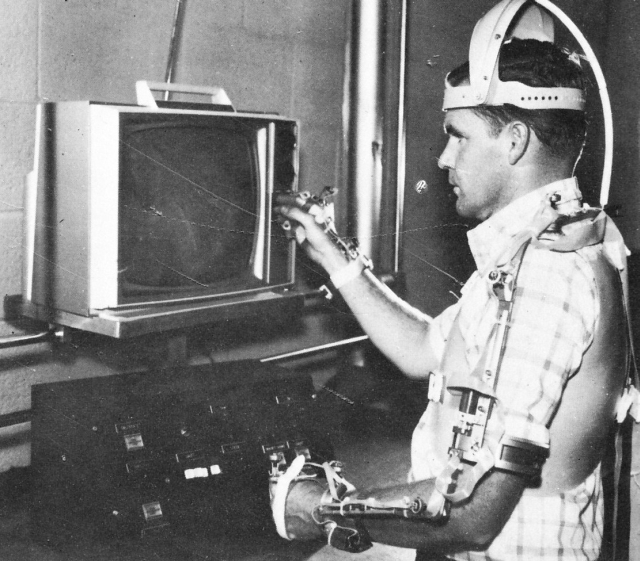

The operator wears a jacketlike apparatus called an "exoskeleton" to send commands to SAM's hands and arms. If the operator wants SAM to pick up a stick, he simply reaches down and performs the necessary hand-arm movements. The operator is able to see the stick by means of a television screen in the control center which presents the picture transmitted by SAM's television camera. Scientists plan to "slave" the movements of the television camera to those of the operator's head. The camera will thus become the operator's remote but all-seeing eye.

The first SAM was built at the Nuclear Rocket Development Station located at Jackass Flats, Nevada. It inspects and tests equipment used at radioactive nuclear test sites. It is planned that SAM-type units of the future will be used to defuse and dispose of dangerous bombs, and as search and rescue vehicles in any type of disaster that involves fire or hazardous fumes, not just those caused by nuclear explosion.

Machines such as SAM suggest a wide array of applications. Teleoperators could be put beneath the sea or on a distant planet and be made to perform a variety of chores, all while under the precise command of a human operator housed in the safety of an earthbound control center.

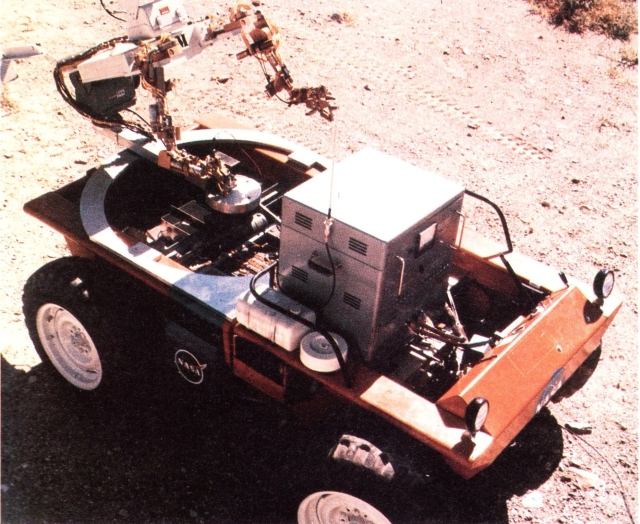

From an overhead view, SAM looks like this.

Using an exoskeleton and guided by what he sees on the television screen, the operator controls SAM with simple arm-hand movements.

It is clear from this image that the anthropomorphic arms are actually Rancho Los Amigos Hospital arms originally designed for disability patients.

Source: Popular Science March 1971

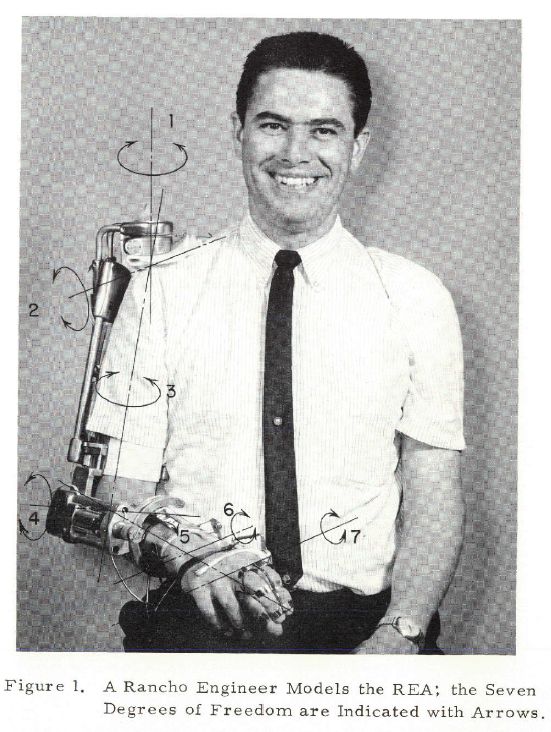

Above: The earlier Ranch Electric Arm.

Orthotic manipulator arms. A man in space is relatively helpless in many respects; to perform useful work, he has to have special tools and some kind of assisting control mechanisms. The Atomic Energy Commission (AEC) has long been interested in perfecting remote manipulators for safely handling radioactive materials from a distance by human operators. These interests coincided with some of NASA's interests, and both groups recognized the significance of advances in externally powered arm braces that had occurred at Rancho. The combined efforts of all three organizations have advanced the sophistication of remote manipulators and of externally powered orthotic manipulators.

Orthotic manipulators resemble the human arm in construction and operation. In medical applications they restore arm function to paralyzed patients, while industrial, scientific, and space uses emphasize "teleoperator" characteristics in a master/slave mode that duplicate human motions at a distance.

NASA and AEC sought Rancho Los Amigos Hospital assistance in improving teleoperators largely because of the hospital staff's success in developing a powered orthosis, the Rancho Electric Arm (REA). Beginning in 1959 with pneumatic (compressed air) power sources,

Rancho investigators determined that a functionally useful arm must have at least seven joints, or degrees of freedom, and they specified optimum alignments, locations, power requirements, angular velocities, and functional ranges of motion. In addition, they ascertained the characteristics and potential of control sites in various types of patients. Intensive analyses of normal arm motions enabled the team to specify operational mechanical configurations to approach as nearly as possible a duplication of normal arm function (see Figure 1).

After four years of work with pneumatic power, it was decided that an earlier consensus in the profession–that electrical power was inferior to pneumatic power (National Research Council, 1961)–was no longer valid enough to preclude new explorations in electric power and control systems. The advantages of pneumatic systems were recognized: weight and cost of actuators were less than for electrical actuators; less noise is generated in the pneumatic system; and complex pneumatically powered orthoses were as much as 30 percent less costly than comparable electrically powered units. However, the advantages of electrical systems were more numerous and compelling. Among these are the greater ease and cheapness of replenishing the power source; greater efficiency of energy storage (by a factor of 10); no need to convert electronic control signals for pneumatic actuators; greater simplicity, versatility, and inexpensiveness of control signal processing units; availability of mass produced, low cost electronic components (versus individually produced costly pneumatic components); availability of a rotary output from an electrical actuator, which meets the need for rotary motion of the dynamic joints of an arm brace without a mechanical conversion of linear to rotary motion; and, very significantly, the ability to use a single energy system to provide ample power for both a wheelchair and an orthosis.

Development of the REA thus proceeded from the broad foundation of successful experience with pneumatically powered orthoses. By early 1965 an operational electric arm had been fitted to a patient for complete testing, evaluation and necessary modifications. Using the current version of the arm, this patient, who became a quadriplegic polio victim in 1954, is now able to perform many ordinary tasks of daily living, including writing, typing at 25 words per minute, and operating a modest telephone answering business.

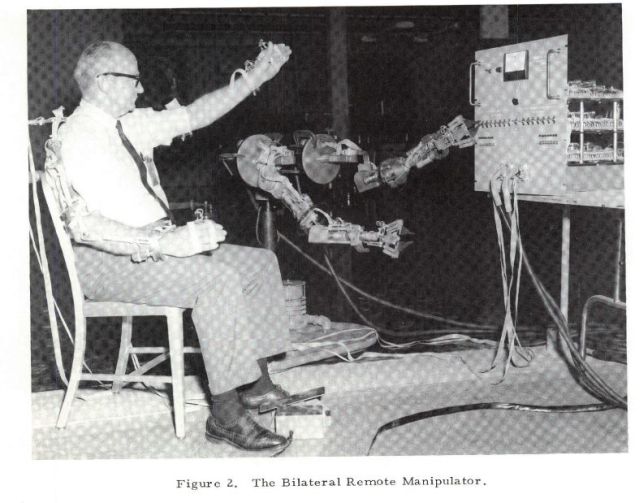

Under contract to Marshall Space Flight Center, Rancho's orthotic arm expertise has been directed toward development and fabrication of four remote manipulators. A bilateral remote manipulator delivered to Marshall was based on earlier arm designs and incorporated several improvements. Among these were two redesigned joints in the master controller brace and lighter, stronger, and more efficient slave arms (see Figure 2).

A self-propelled anthropomorphic manipulator (SAM) was built for use at the Atomic Energy Commission's Jackass Flats nuclear engine facility. SAM is mounted on a motorized vehicle that is remotely controlled by telemetry as it travels about an area of hazardous radioactivity. The manipulator arms are also remotely controlled to do useful work in the hazardous environment. Finally, the Rancho Anthropomorphic Manipulator (RAM) exists as a demonstration prototype. RAM has the capability of operator-controlled terminal device replacement. It is mounted on a "shoulder" that allows side-to-side and forward-backward movement of four inches in each direction, as well as arm movement within the radius of the arms. Its size and power are much greater than those of the Rancho Electric Arm; RAM can lift and transport a ten-pound weight. Several control systems can be used, including a joystick. Development emphasis has been on a master/slave system with an exoskeleton control apparatus for the operator.

Beyond the immediately useful improvement of teleoperators that enable men to perform work in hostile environments, these research and development activities have enhanced Rancho's expertise in its area of major concern: rehabilitation of the disabled.

2006: Centaur

NASA JSC has developed a series of Centaur rovers to carry the Robonaut upper bodies and other payloads. Centaur 1 was developed for work with the Robonaut R1B humanoid upper torso in 2006. Centaur 2 rover was developed in 2010 by the Human Robotics Systems (HRS) Project as part of the Exploration Technology Development and Demonstration Programs, and has now been integrated with the Robonaut R2A torso. This combination mixes state-of-the-art robotic mobility with the world’s most advanced dexterous manipulation system. Hybrid rover/arm systems, commonly referred to as mobile manipulation, represent a new domain of robotics research. Mobile manipulation is an important new Space Technology with multiple applications for improving life here on Earth. NASA’s new Centaur2/Robonaut2 system is an ideal testbed for this research and positions the agency as the technological leader.

See other early Teleoperators here.

See other early Lunar and Space Robots here.

Done – sorry for the incorrect spelling.

Excited to see this article on my father’s work SAM– Please, please correct spelling of last name to Johnsen, yes, SEN is correct, name used to be the Danish Johansen. your newest fan, M C Johnsen, daughter.