ROMAC, THE PNEUMATIC MUSCLE

Actuator pulls 10,000 pounds using 60 psi

A pneumatic actuator based on the principle of the human biceps has come to our attention in the form of a patent disclosure. The ROMAC, under development by MacDonald Detwiller & Associates of Richmond, British Columbia, Canada, works on low-pressure (shop) air and can lift over 200 pounds using 60 psi. The device weighs one pound. Its pulling force is said to exceed 10,000 pounds, rendering it superior to conventional pneumatic cylinders and nearly in the range of comparable hydraulic cylinders.

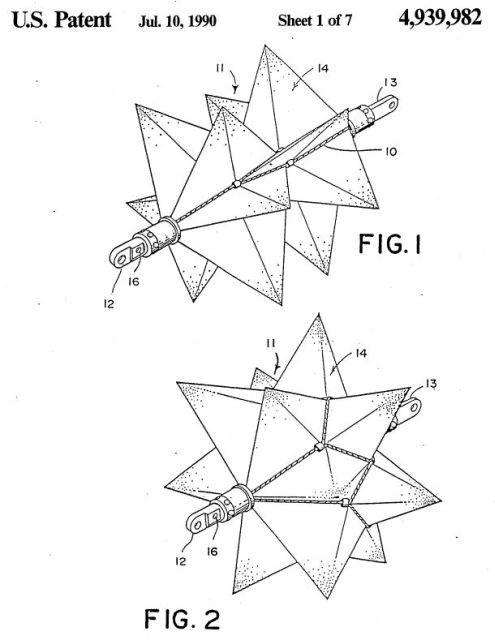

The flexible walls of the ROMAC are not designed to work as elastometers. Rather, the geometry of the individual pyramid elements allows for greater contraction. Additionally, the wire restraining cables and pyramid elements are combined into a "single surface" actuator designed to eliminate sliding friction during contraction, reducing wear on the soft parts and extending service life.

The device operates only under tension. Like the human biceps, it bulges in the middle as it contracts and flattens with

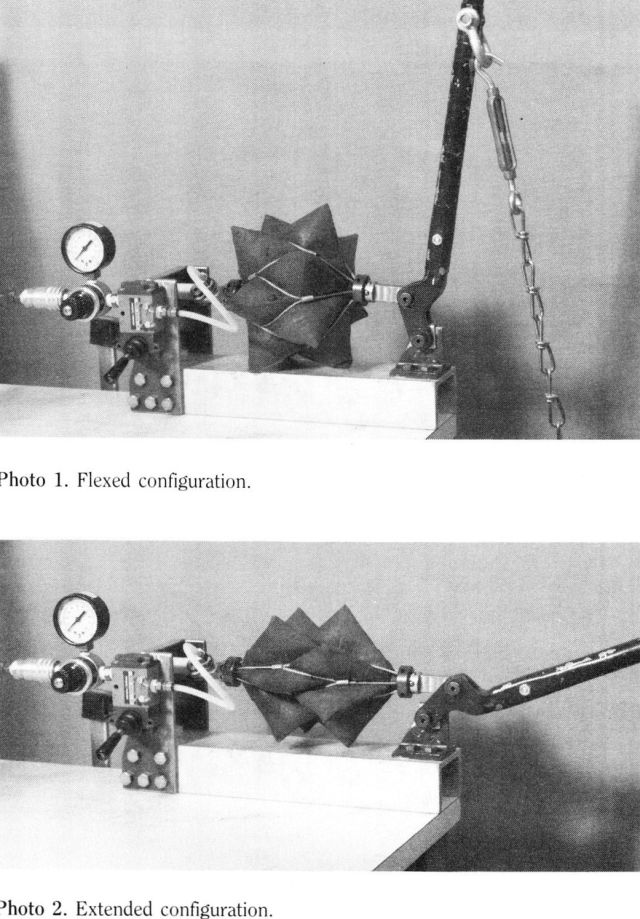

extension. In Photos 1 and 2, the ROMAC is manually manipulated by means of a lever to demonstrate its flexed and extended configurations. The potential contraction is 50 percent. The actuator is said to provide an extremely high force at the beginning of contraction, decreasing rapidly to zero at approximately 50 percent of contraction (Figure 1). The ROMAC's other advantages, as described, include the following:

• It is pneumatically powered but can also work with low-pressure hydraulics.

• It is leak-free, with no sliding seals and no static friction.

• It can be fabricated without metallic parts. (Fiber glass could be substituted for wire in the restraining cables.)

• It can be configured to do precision closed-loop control tasks.

• In opposing pairs, it can provide open-loop proportional control with inherently stiff operating characteristics.

Because of its high initial pulling force and its ability to perform in hostile surroundings, the ROMAC is expected to number among its future applications robotics, prosthetics, and nuclear and space environments.

[Source:The Robotics Age Nov 1985 – Edited by Stephanie vL Henkel]

Like the muscle used in Tim Jones' arm, the ROMAC is another example of the Netted-type of Pneumatic Artificial Muscle (PAM).

Axially contractable actuator by Guy Immega and Mirko Kukolj

Patent number: 4939982

Filing date: Oct 16, 1985

Issue date: Jul 10, 1990

See full patent details here.

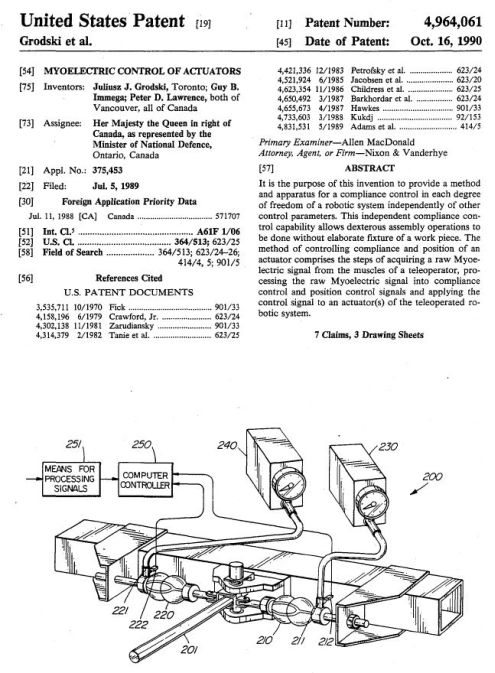

Grodski and Immega used ROMACs to control a 1-dof teleoperated arm by means of the myoelectric signals taken from a human operator's biceps and triceps. The operator can thus make the robot arm move without having to move his own. Independent position and stiffness control of the robot arm is achieved by regulating the ROMAC gauge pressures proportional to the operator's EMG signal output. Visual feedback to the operator is necessary.

Myoelectric control of actuators Juliusz J. Grodski et al

Patent number: 4964061

Filing date: Jul 5, 1989

Issue date: Oct 16, 1990

See full patent here.