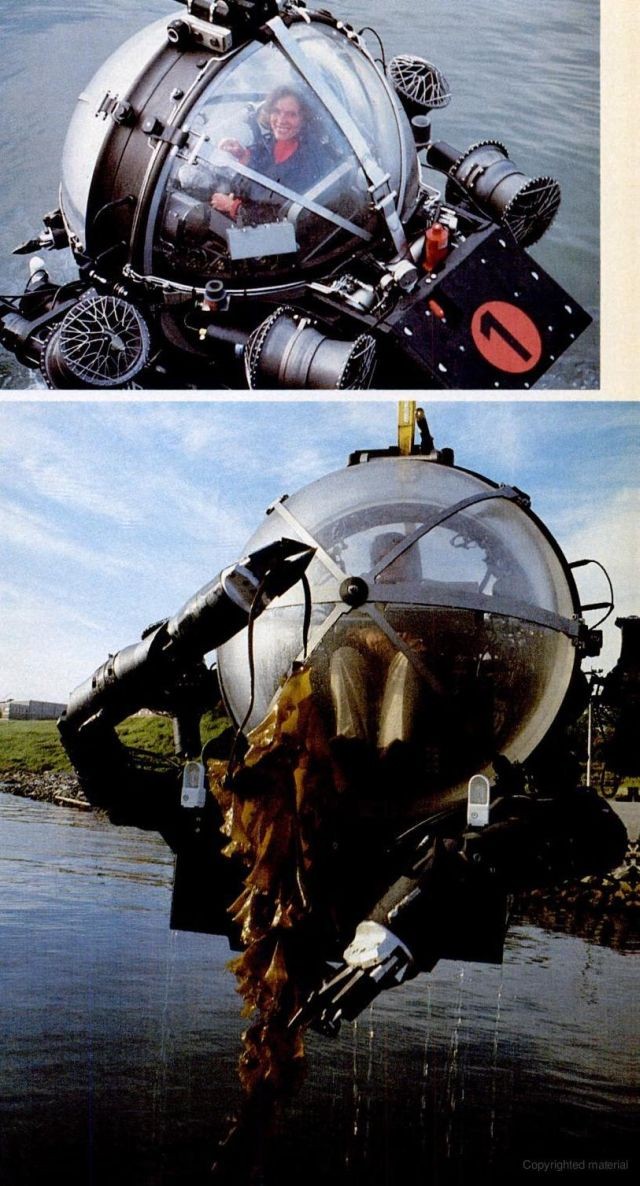

1981 – "Deep Rover" Submersible.

See 7:10 into the Video.

Top: Dr. Sylvia Earle. Bottom: Graham Hawkes.

Extract from Popular Science, Dec 1984.

An acrylic-bubble undersea habitat called Deep Rover will take oceanographers and oil-rig technicians to depths of 3,200 feet, where they'll work at sea-level pressure—in near-living-room comfort. The vessel "flies" like an underwater helicopter and has a set of manipulators that can lift 200 pounds apiece—or cradle an egg.

Though Deep Rover is expected to find much of its work in offshore oil fields, it was a marine biologist, Dr. Sylvia Earle, the noted oceanographic curator of the California Academy of Sciences, who planted the idea in Hawkes's mind. Three years ago she challenged him with a question: "Why can't we dive in comfort to the bottom of the ocean?" Having logged more than 4,500 hours underwater, she had the right—indeed, the need—to know. Some time later Hawkes, Earle, and Phillip Nuytten (president of Can-Dive, a Canadian company that furnishes diving support for offshore oil fields) met for dinner in Seattle. Hawkes, responding to Earle's scientific and Nuytten's commercial inputs, produced an elegant napkin sketch of the plans for Deep Rover.

MANIPS by By PETER BRITTON, Popular Science, Dec 1984.

"Manips": the human connection

Graham Hawkes describes his work as "simplicity through complexity." Deep Rover's elegant manipulators reflect that philosophy. The official name for them is the Sensory Manipulative System. Hawkes calls them the "manips."

Their object is to extend the pilot's reach and use his unmatchable combination of intelligence, experience, depth perception; and eye-hand coordination. "We rely on the human brain rather than a computer to operate the system," says Hawkes. "If the pilot's hand is trembling, the manip will tremble in sympathy, down to about five cycles per second," he adds. The manipulators are of such dexterity and response that NASA is considering them, along with a Deep Rover-like vehicle, for excursions and work from the space shuttle.

Made of aluminum, stainless steel, and graphite-loaded nylon, the modular manipulators can vary in length from 5.6 to 7.5 feet and weigh up to 150 pounds. Each carries a light and a low-profile television camera.

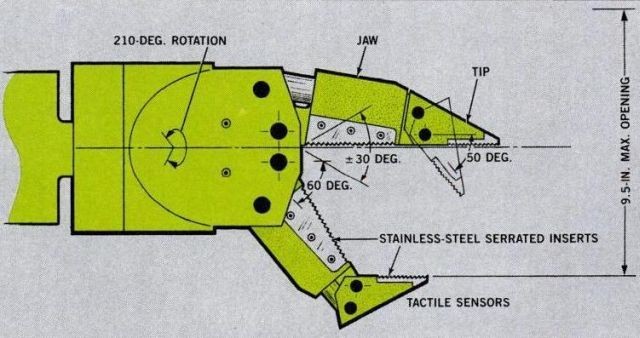

An analogy with the human arm and hand is useful in grasping the concept of degrees of freedom, and hence what the manipulators can do. An extended arm can (A) move up and down and (B) move from side to side. It can (C) bend at the elbow. The wrist can (D) move up and down, (E) move from side to side, and (F) rotate. And the hand can (G) open and close.

The complementary manipulator motions are activated through the handgrip by moving it backward and forward (resulting in action A), side to side (B), and by rotating it (C). A thumb switch on top is moved up and down (0) and side to side (E) to control the wrist. Two buttons rotate the wrist clockwise or counterclockwise (F), and a trigger opens and closes the "hand" (G).

The four-function "hands" each have two large jaws and two tips. When the serrated edges of the large jaws touch an object and close on it, the force is instantly transferred to the tips, which then also close. When a four-point contact is achieved, a steady grip

occurs.

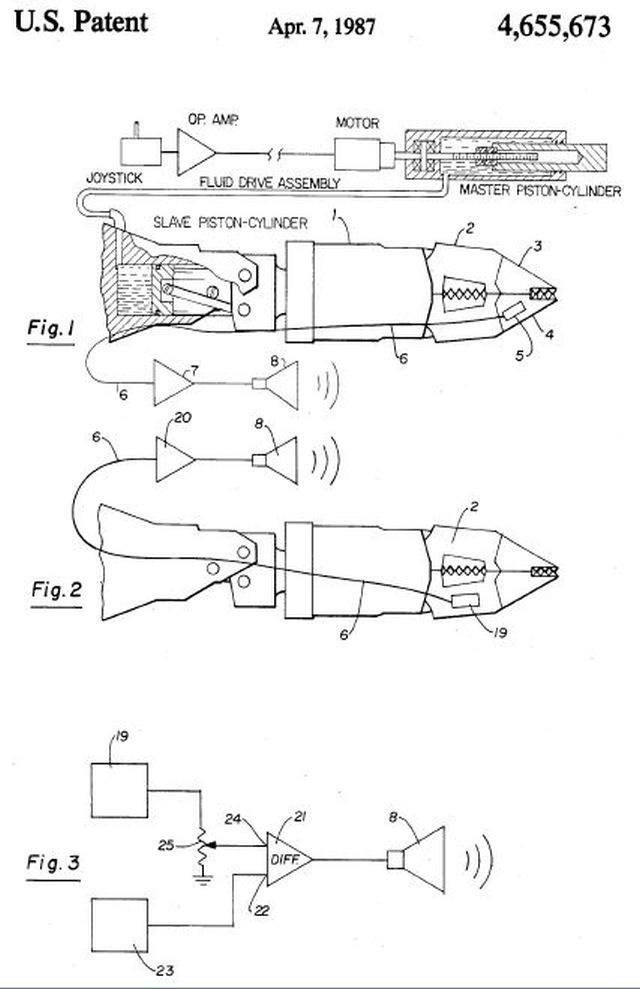

The manips employ five elements of sense (some details of which are proprietary): sight, motion, force, sound, and touch. For the manips the tactile sense is the most important. But it is not touch as we know it.

Hawkes explains: "Robots generally are designed to recreate a sense of touch by sensing remotely in the manipulator and conveying that sense to the pilot through electrical readouts. But the readouts mean nothing by themselves and must be translated. What we do is translate the tactile sense into an audio signal and feed it to the pilot through his ears.

"We're using accelerometers, and we get a sense that is analogous to the sound that comes from scraping a brick with a fork. However, we pick up not sound but accelerations in the jaw tips—vibrations, if you like."

In operation, a pilot could probe below the mud line with the manips and correctly identify whatever material he "touched," be it plastic, metal, wood, or concrete, through the sound from the cockpit speakers. A trainee, according to Hawkes, can learn this new "language" in about two hours.

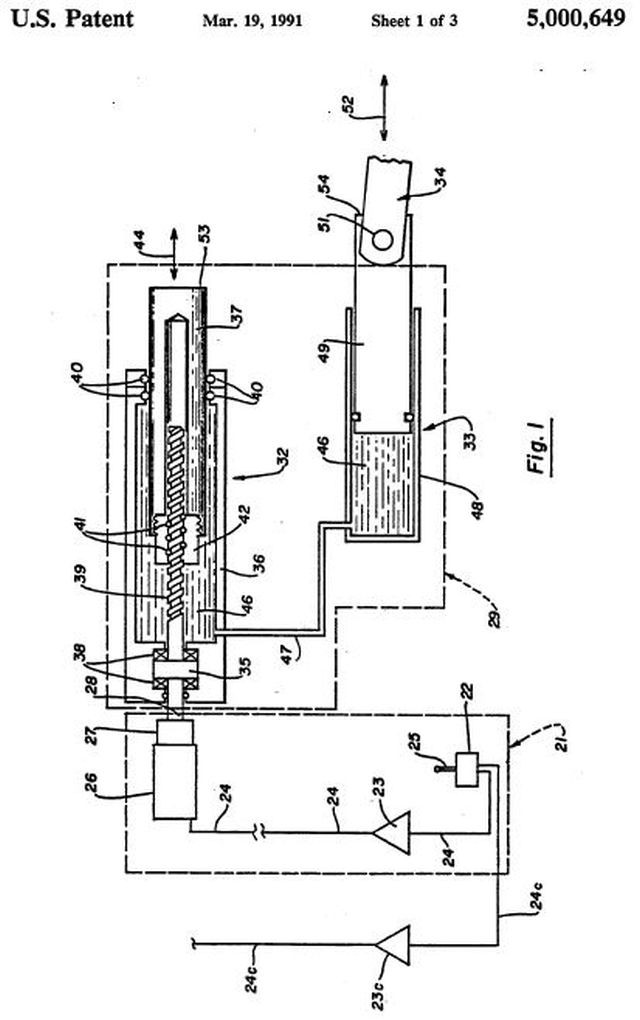

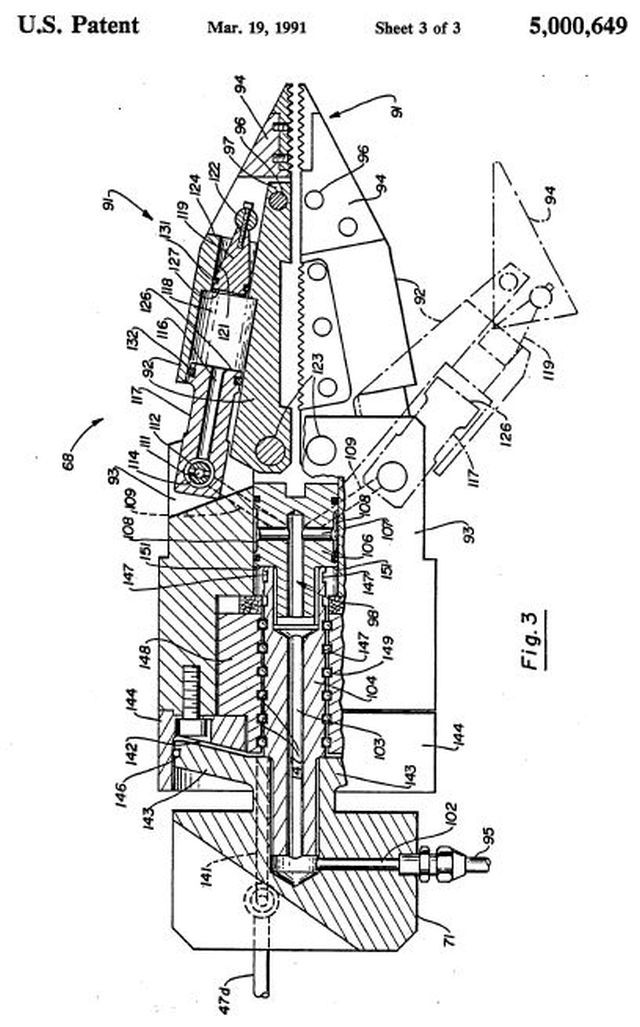

This function operates in real time, and Hawkes designed the manipulators to respond quickly—through a combination of electronics and hydraulics—so that the pilot can take full advantage of it. When the pilot commands a manip through the handgrip, he activates a motion switch built into the controller. An electrical signal goes from the controller to a power amplifier, which puts out an electrical signal that drives an actuator outside the hull. There is one actuator for every function on each manipulator.

The actuator converts the electric signal to hydraulic power through a gearbox and a lin-ear/rotary ball-bearing unit, which causes the displacement of a piston. This forces hydraulic fluid out of the actuator and into the manipulator, where a joint is moved—or a jaw is clenched. Withdrawal of the fluid causes a motion in the opposite direction.

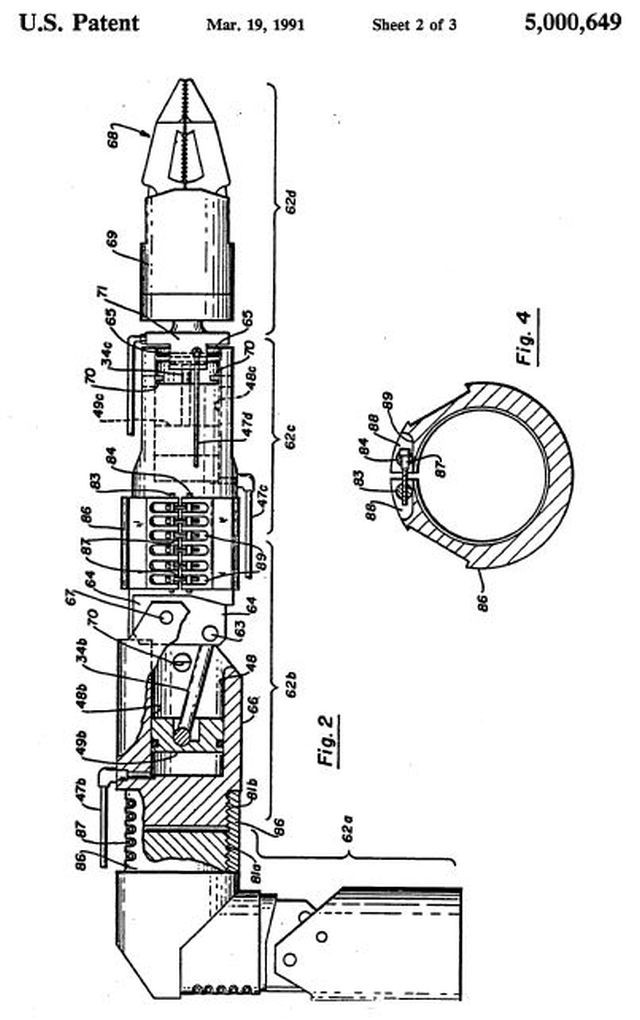

Related Patents.

Electromechanical manipulator assembly

Publication number US5000649 A

Publication date 19 Mar 1991

Filing date 22 Aug 1986

Priority date 15 Feb 1983

Inventors Graham S. Hawkes

Original Assignee Deep Ocean Engineering Incorporated

Description

This is a continuation of application Ser. No. 466,606, filed Feb. 15, 1983, now U.S. Pat. No. 4,607,798.

BACKGROUND OF THE INVENTION

The present invention relates, in general, to remotely-operated, manipulative devices and relates, more particularly, to underwater or sub-sea, remotely-controlled, powered manipulator arms.

In recent years the use of manned and unmanned underwater apparatus to explore and develop natural resources has increased dramatically. In the petroleum industry, for example, off-shore drilling has required both manned apparatus (submersibles) and unmanned underwater apparatus (robotic devices) which are capable of performing a wide variety of manipulative tasks. Typically such apparatus includes one or more remotely operated, powered arms which have a terminal device, such as claws, pincers or jaws, which are analogous to a human hand. The manipulator arms are usually jointed or have several axes of movement and may be controlled in a preprogrammed manner or by a remotely-operated input device. Such manipulator assemblies are exposed to very adverse environmental conditions, particularly when operated in bodies of salt water at substantial depths, which is the normal operating environment for most off-shore oil exploration and recovery equipment.

Prior underwater, electromechanical manipulator apparatus have typically employed a D.C. motor coupled to a hydraulic pump as the primary power for actuation or moving of the arm assemblies. The hydraulic pumps are coupled to a hydraulic circuit employing solenoid valves to control displacement of the manipulator arms and operation of the claws or jaws on the end of the arms.

If these prior art solenoid-based manipulator systems are relatively simple, the operating characteristics have been found to be poor. The smoothness and dexterity of movement with Which the arm and claws can be manipulated are not satisfactory for many applications. In order to attempt to have a smoothly operating solenoid valve- based system, the valving and pump controls can be made very complex, but the resulting complexity substantially increases cost and the incidence of breakdown.

Another prior art approach to underwater manipulative assemblies is to employ a D.C. motor-feedback servo amplifier system in which the motor directly drives the mechanical elements in the arm. Such a direct coupling of the D.C. motor to the mechanical manipulator elements has been found to require extremely close tolerances with attendant undesirable cost. Moreover, there are substantial shock loading problems in the gearboxes of such systems.

A remotely operated, underwater manipulator assembly should be capable of smooth motion over a wide speed range. Thus it should be able to move uniformly and smoothly at low speeds for precise work and smoothly at high speeds for rapid arm positioning. Underwater manipulator assemblies also should be able to exert a variable force at any of the speeds in its range of operating speeds. Moreover, a remotely operated underwater manipulator arm or assembly should have the capability of simultaneous and cooperative motion in two or more directions to give full freedom of movement of the terminal device or gripping jaws. The combination of smooth functioning over a wide speed range, variable force throughout the range, and multidirectional movement provides an underwater manipulator arm assembly which begins to closely approximate the motion and dexterity of a human arm and hand.

Additional related patents:

Publication number US4471207 A

Apparatus and method for providing useful audio feedback to operators of remotely controlled manipulators

Publication number US4655673 A

Apparatus and method for providing useful tactile feedback to operators of remotely controlled manipulators

See other early Underwater Robots here.