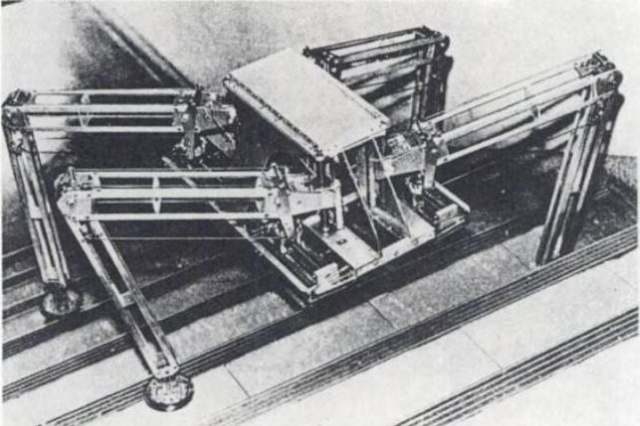

Photo.2 Sensor based stair climibing walk of the PV-II.

KUMO-I (1976, see here), PV-II (1978-1979, Photo. 2). The method of locomotion called “walking” requires considerably more actuators than the wheel me thod of locomotion, the drive system is heavy; and it is not simple to control. However, walking machines, because they can move while separately selecting the point of leg contact with the ground by adapting to the shape of the terrain, are fully practical, depending on the use, because they have such characteristics as:

1) Can move stably over a rugged surface, and can pass over fragile objects on the ground surface without touching them.

2) Can make holonomic omnidirectional motion without slipping or damaging the ground surface.

3) Utilizing the degrees of freedom of the legs it can become a stable and active platform even on a rugged surface when stopped for some manipulation task.

We have been working on walking machine research since 1976. As for the number of legs, we selected four, which is the minimum number capable of executing statically stable walk. Photo. 1 (here) is the first generation model “KUMO-I”, that was first manufactured on the model of a daddy-longlegs spider and that has a leg length of 1.5 meters and a weight of 14 kg. Photo. 2 is a second generation model (PV-II). The leg length is 0.9 meters and the weight is 10 kg.

Fig.1 Power consumption generated by the hips and knee joints during horizontal locomotion (The negative power cannot be regenerated, and a large amount of energy is consumed.)

When a leg is designed as shown in Fig. 1, the actuators on hip and knee joints consume positive and negative power, but a normal actuator can not regenerate the negative power. For this reason, a large amount of energy is lost. We found out that this is the reason why the energy efficiency of conventional walking vehicle is so low. In order to improve this, GDA (gravitationally decoupled actuation; a drive system configuration method that separates drive in the gravitational direction and drive in horizontal direction) shown in Fig. 2 was introduced into the prototype model. Fig. 3 indicates the 3-D pentagraph mechanism for GDA that was utilized in the PV-II. This expands the prismatic motion of the three orthogonal axes provided on the torso part, lightens the legs, and simplifies their control. In 1979, the PV-II was the world’s first success in sensor based stair climbing utilizing leg-end tactile sensors and posture sensors.

Fig.2 A leg mechanism that prevents the negative power loss of Fig.1

1. Orthogonal coordinate mechanism (basic form)

2. The mechanism used in KUMO-I

3. The 2-D pentagraph mechanism

Fig.3 The newly developed three-demensional pentagraph mechanism and leg-end orientation control mechanism

References:

1. Shigeo Hirose, Yoji Umetani; Some Consideration on a Feasible Walking Mechanism as a Terrain Vehicle, Proc. 3rd RoManSy Symp., Udine, Italy,, , pp.357-375 (1978)

2. Shigeo Hirose, Yoji Umetani; The Basic Motion Regulation System for a Quadruped Walking Vehicle, ASME Publication 80-DET-34,, , pp.1-6 (1980)

3. Shigeo Hirose, Yoji Umetani; A Cartesian Coordinates Manipulator with Articulated Structure, Proc. 11th Int. Symp. on Industrial Robots, Tokyo,, , pp.603-609 (1981)

Just found fabulous footage of this walker plus others. 50meg download. mp4 runs for 16 mins. see here.

See other early Walking Machines here.