LOCKHEED AIRCRAFT CORPORATION

LOCKHEED-GEORGIA COMPANY

MARIETTA, GEORGIA

INTRODUCTION

The first manipulative tasks required of man in a space operation will be those associated with establishing a station in orbit or with operating a manned vehicle or station in orbit. Practical environmental control systems required for human survival will probably result in performance degradation at best and total incapability at worst.

It in assumed that a human operator will be necessary to monitor, control, or perform assembly and repair operations in space. The various degrees of human input in increasing order of human contribution are thus typified in

a. Self-repairing or self-assembling systems

b. Robot-repairing or robot-assembling systems

c. Human operator-repairing or human operator-assembling systems.

The Self-repairing or self-assembling systems are systems which are completely mechanised. Since the space environment will not affect their basic functioning substantially, only monitoring is necessary.

The robot-repairing and robot-assembling systems add mobility to the required operations. However, such systems have seldom proved satisfactory in the earth environment and their deficiencies are compounded in space.

The most useful and the most promising vehicle systems are those which utilize, in the most direct manner, human capabilities. The equipment which maintains a habitable environment for the human operator while accomplishing his task and the equipment which provides the means of performing the tasks are considered to constitute a vehicle system.

A detailed theoretical study on construction of specific space systems for remote landing does not seem to be warranted until simulation is available to confirm the analysis. Thus, development of a simulator with this capability is essentlal. Recognizing this, the Georgia Division of Lockheed has established some broad requirements for space systems and is using them to study and establish simulator requirements and concepts.

THE VEHICLE SYSTEM CONCEPT

A general description of one type of vehicle system that might be used for remote handling in space is presented to illustrate how simulation of such a system might be accomplished. A typical sequence of tasks to be accomplished in space station assembly might be:

a. Secure components to prevent drift.

b. Locate specific component package.

c. Restrain component and move to assembly area.

d. Remove protective covers and prepare for assembly.

e. lndex components to be assembled.

f. Hold indexed components during attaching act—such as bolting, riveting, or welding.

g. Seal and make wiring and plumbing

Once the primary need and mission of such a vehicle system is established, secondary applications should be studied. Such applications for a space station assembly and maintenance vehicle system might be:

a. Recovery of payloads boosted to the vicinity of a space station

b. Transfer of personnel or cargo between space stations

c. Emergency escape

d. Satellite inspection

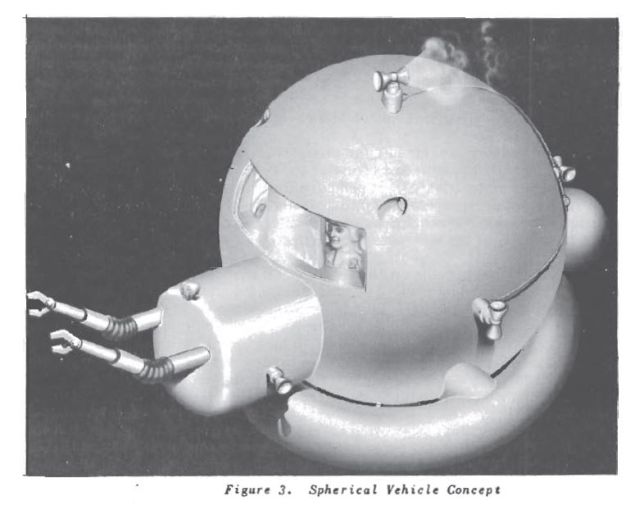

Studies and reports made by Lockheed-Georgia Division indicate that the best vehicle systems will probably result from a philosophy which minimizes vehicle mass. Due to the environment and basic physical relations, it seems unlikely that any "Sunday Funny" type space suit will be practical. Thrust nozzles will be fixed to a rigid frame and have some degree of automatic control. Such a system requires fuel for accelerating and then decelerating. If the vehicle mass becomes excessive, the amount of fuel required becomes large and aggravates the situation. By assuring that research and test equipment is designed into the space stations rather than into these utility vehicle systems, a lightweight vehicle system should evolve. Examples of such systems are shown in figures 1, 2. and 3. These concepts are described in refs. 1 and 2.

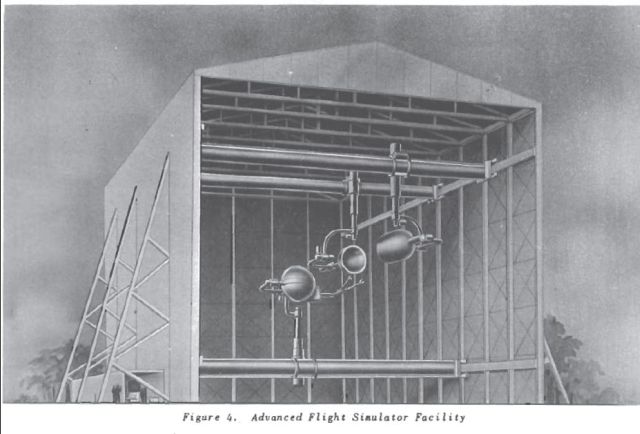

By means of curtains, lights, and projectors the external visual environment can be simulated.

A combination of insulation and recordings can provide the proper aural environment.

This simulator would permit development of remote-handling systems and design of space equipment which would be tested prior to launch. Training of operators for the vehicle systems and handling equipment should be invaluable as training of operators for hot laboratory manipulators now is.

In summary, the best remote-handling space system should result from the proper matching of the operator and equipment. One of the best means of achieving this matching is by simulation. Such simulation can hardly be postponed further since the results of studies would be invaluable in designing the first space systems requiring handling, assembly or repair operations, and in training the men who will operate them in space.

REFERENCES

1. Space Station Assembly and maintenance. ER 3469, Lockheed Aircraft Corporation.

2. Space Suit Design Study, ETP 186, Lockheed Aircraft Corporation-Georgia Division,

3. An Advanced Slight Simulator, ETP 152, Lockheed Aircraft Corporation- Georgia Division, Marietta, Georga, March 1959.

Source: "Survey of Remote Handling in Space", D. Frederick Baker, USAF, 1962

See other early Manned Space Manipulators and Teleoperators here.

See other early Lunar and Space Robots here.