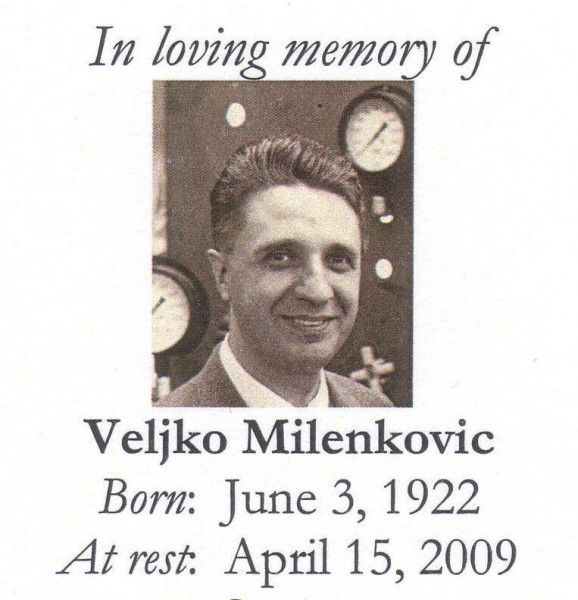

In 1958, the American Machine and Foundry (AMF) Thermatool Corporation (later known as AMF Corporation, later acquired by Prab Company of Michigan) initiated an R&D project for a Versatile Transfer Machine, or VERSATRAN, a programmable cylindrical coordinate frame robotic arm designed by Harry Johnson and Veljko Milenkovic. AMF introduced Model 102, a continuous-path transfer device, and Model 212, a point-to-point transfer device, in 1962.

AUTOMATIC HANDLING EQUIPMENT CALLED 'VERSATRAN'.

3243.02 | AUTOMATIC HANDLING EQUIPMENT CALLED 'VERSATRAN'. (1:02:10:00 – 1:05:52:00) 1967

Hatfield, Hertfordshire. Date found in the old record – 23/02/1967.

Various shots of the 'Versatran' – an artificial arm and a hand construction grab which is controlled from large panels. Developed in the USA by American Machine & Foundry Company. The grab is seen picking up a large bobbin and placing it in a box. The control panel can be programmed in advance so the grab can be operated in advance. Demonstration by Mr D C Hall.

It was only in 1967 that the Tokyo Machinery Trading Co. in Japan imports and sells the first industrial robot, a Versatran from AMF, Inc. Britain aquires its first Industrial Robot, a Versatran, in 1967, by Douglas Hall, as seen in the video clip above.

RISE OF THE ROBOTS by George Sullivan 1971

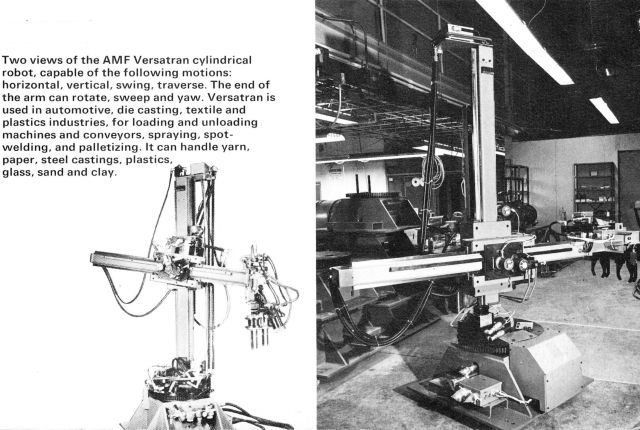

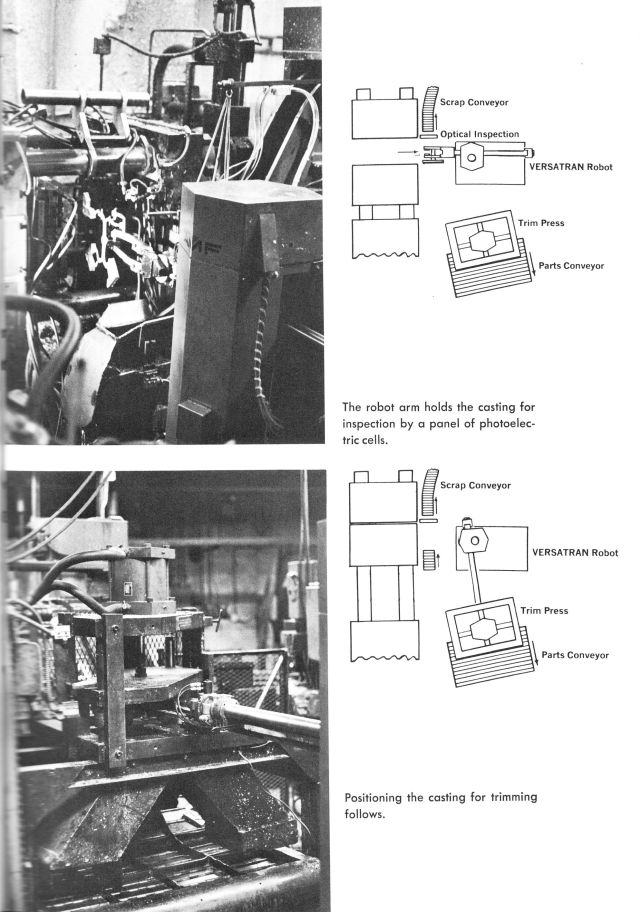

A second industrial robot arrived upon the scene in 1963. Manufactured by a division of AMF Thermatool, Inc., this robot is called the Versatran ( from versatile transfer ). It is characterized by a sturdy horizontal arm coupled to a six-foot vertical steel column which is mounted on a rectangular base.

Although they [Unimate] are different in appearance, the Versatran robot and the Unimate have many similarities. Both can handle objects weighing over 150 pounds. Both are built to last for forty thousand working hours. They sell for about the same price, approximately $25,000 [1971].Industrial Robots at Work

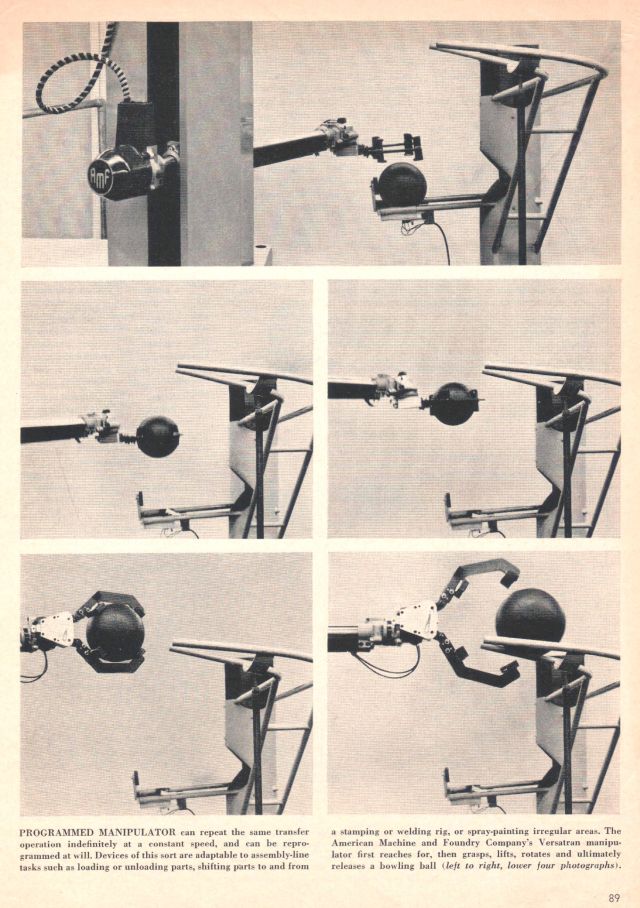

Industrial robots do work of every imaginable type. They spray-paint automobile engines and spot-weld auto bodies. They stack brick and pluck hot parts from presses and die-casting machines.

What the robot does depends on its program. With the Versatran robot, there are two types of program controls. One is called point-to-point control and is the type used for relatively simple jobs. The other, for more complex tasks, is called continuous-path program control.

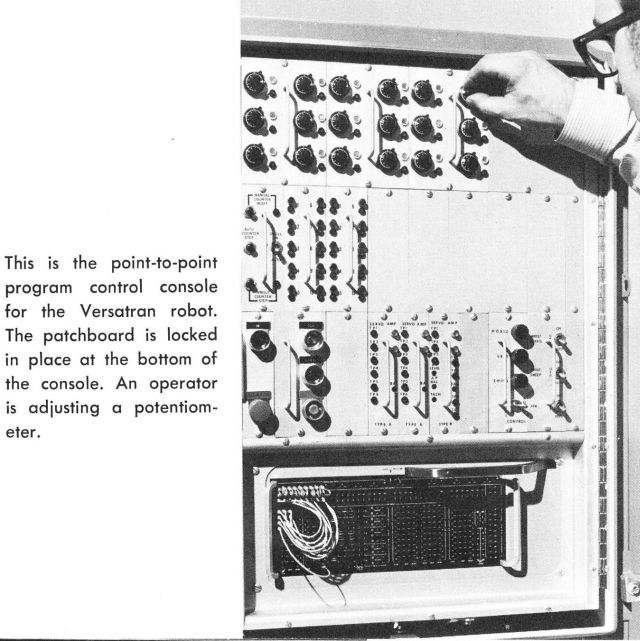

When programming a point-to-point control operation, the arm movements and functions to be performed are first drawn on a piece of paper. Then this sequence of "orders" is translated into electronic signals. Short lengths of metal-tipped wires, known as "patch cords," are inserted into the holes of a small, black pegboard, called a "patchboard," to correspond to the written orders.

The programmed patchboard locks into the robot's console panel. The board's contacts connect with memory-storing and command devices known as "potentiometers." Once the potentiometers have been adjusted for the various arm positions in the cycle, the machine is ready to operate. The robot user may own several patchboards, each programmed for a different job.

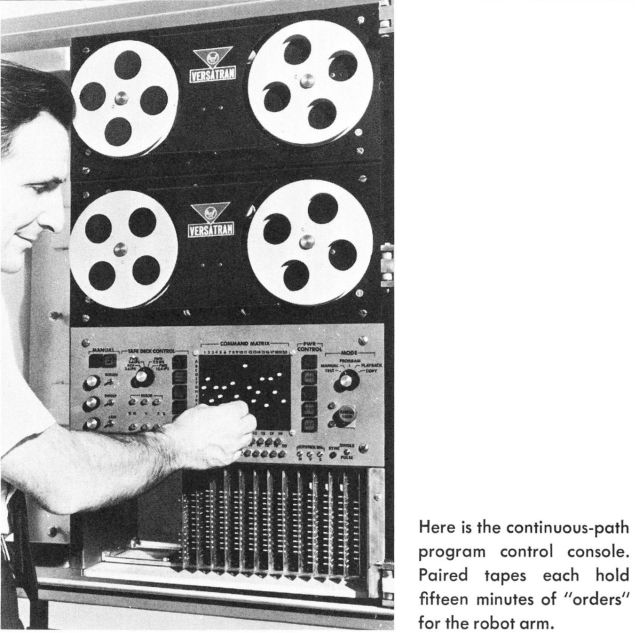

Programming the Versatran robot for "continuous path" operation is a matter of "teaching" the machine the proper motions to follow. A switch in the console is set for "program." The operator then leads the robot arm through all the motions it will later assume on its own. Gripper commands are also acted out. These signals are automatically recorded on magnetic tapes within the control console. There are fifteen minutes of program time available on each of the two reels of tape the console contains.

The Unimate is programmed in similar fashion—by moving the robot arm through the desired sequence of operation. The sequence registers in the machine's memory unit. Once the robot arm has been "taught" a program, it will follow the prescribed set of operations over and over.

"There's no mystery to programming," says one user. "It doesn't even require a mechanical background, much less a knowledge of electronics."

The job the robot is programmed to do may involve several individual tasks.

See Harry Johnson and Veljko Milenkovic related US patents US3212649, US3241020 and US3298006.

-x640.jpg)

See Milenkovic tribute and mention of Versatran development here.

VERSATRAN robot in the 1971 movie "Silent Running"

The "billiard's" playing robot is actually an AMF Versatran industrial robot.

Regarding "Silent Running", for a 1972 movie, the Versatran was still considered a state-of-the-art industrial robot.

Two interchangeable end-effectors are shown, a gripper for loading/depositing billiard balls, and a pneumatic "cue" to strike the ball (below). The standard two-fingered Versatran gripper picks up a B.A.S.E.(tm) 3-fingered gripped to deposit the balls. Another small continuity error in that when picking up the B.A.S.E.(tm) gripper, the 2 pneumatic lines are not attached, but then magically appear in the next shot (see above). Also in the above image is the AMF Versatran name/logo, as well as the controller on the left.

The control panel in the background is a real and actual point-to-point Versatran control panel, used to program the various movie sequences. Although portrayed as "thinking for itself" , this robot would have to be choreographed and programmed via the point-to-point controller.

See other early Industrial Robots here.

Hi Jim,

In 1979, Prab acquired the Versatran line of industrial robots from AMF. I hope that helps.

Cheers,

Reuben Hoggett / cyberneticzoo.com

I uncovered a piece of machined aluminum 3″ x 3″ x 3/4″ thick that has “PRAB VERSATRAN ROBOTS” etched on one side. Unsure to what degree it relates to the Versatran industrial robot. It was found at the estate of a former Boeing engineer

I did the market research study in 1958 that tested the market for the Versatran. Among other things it indicated there was a need for two sizes. I was working for Stewart-Dougall and Associates in NYC