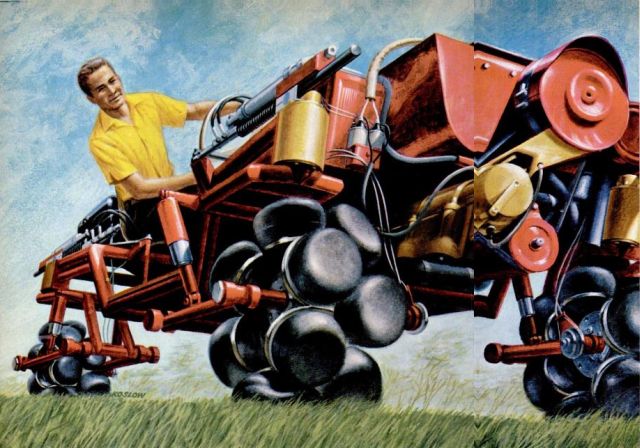

The Incredible No-Torque "Walking" Machine

It can turn on its axis, "walk" sideways, and tackle the roughest terrain and unbelievable gradients

by DAVID SCOTT /PS European Editor

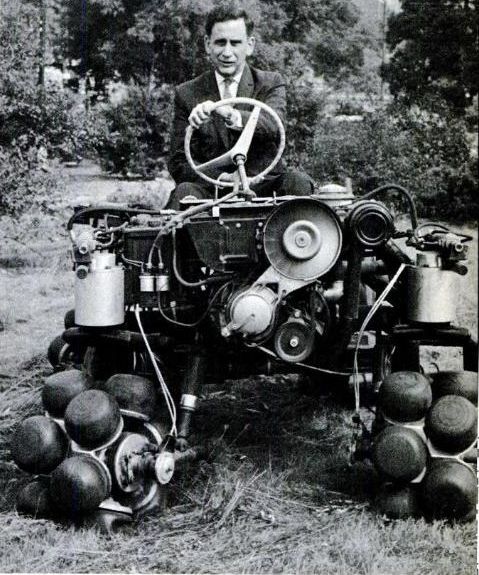

The zaniest ride I've ever had was at the wheel of this weird walking-wheel vehicle on a grassy hillside in a Prague suburb. What's it like? Something like driving over rough cobblestones, but with a trembling waddle rather than a jiggling over the bumps. Though the ride is pretty smooth the clatter of tortured rubber sounds like you're rolling on four flat tires.

Stamp hard on the gas and there's a banshee howl from up front, but acceleration is slow a-comin'. A yank on a lever and suddenly it's full-speed astern. Twist the steering wheel to full lock and you're circling around on your own axis.

Developed at Czechoslovakia's Motor Car Research Institute from an 18-inch-long model built to prove the principle (PS, July '64), the seven-foot Rotoped has wheels that rely on gravity rather than friction for traction. As no torque is applied to them, they won't spin or dig in on sand, mud, or ice. If one bounces off the surface on a bump, it just stops turning, then starts driving again as soon as it hits the ground.

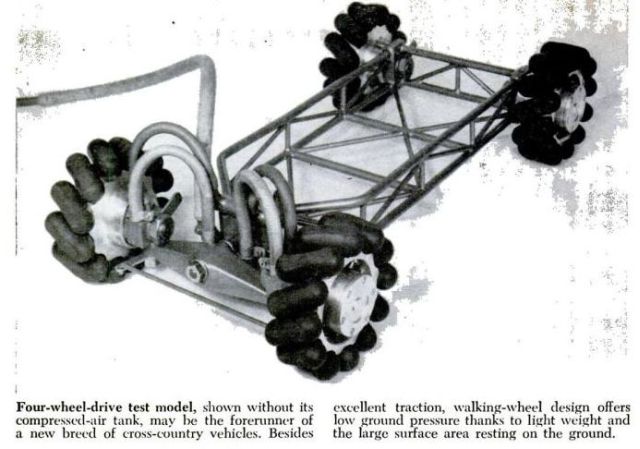

Bypassing friction. Run by compressed air, the self-propelled wheel has many other advantages. The usual mechanical transmission is completely eliminated, together with its bulk, weight, and frictional losses. All-wheel drive is easy, differential action is automatic, and all wheels can be steered for exceptional maneuverability. Rolling resistance is very small, and ground pressure is low, due to the large contact area.

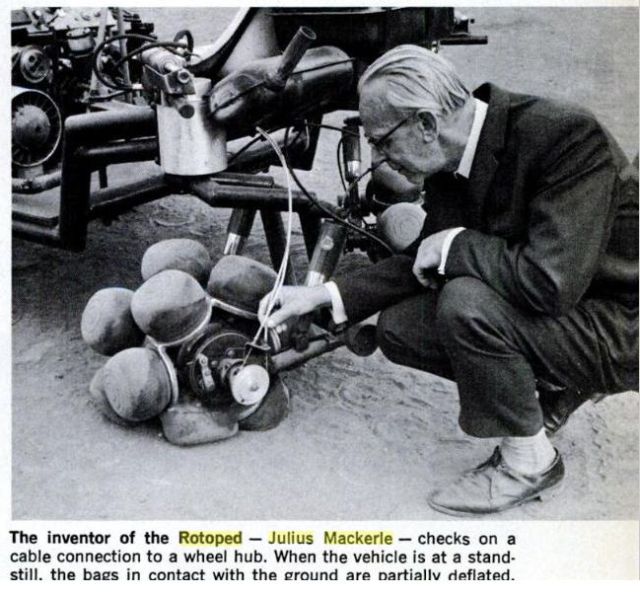

Inventor Julius Mackerle, a senior engineer, at the Research Institute, sees the the machine as an ideal cross-country vehicle, It can move on any kind of terrain, and with further development could climb grades like a horse. And the more wheels the greater the edge over a conventional all-drive multiwheel truck, because of the large number of power-robbing gears and universal joints in the drive-train of a conventional 6 x 6 or 8 x 8.

The wheel—a simple idea. Mackerle studied the movements of a walking man, who first stands an one foot, then leans forward onto his second outstretched leg to make a step. What limits his efficiency and speed is the need to accelerate the first foot forward from rest through to distance of two paces for the next step. The counterweight effect of the leg swinging against the direction of travel tends to oppose the body's forward movement.

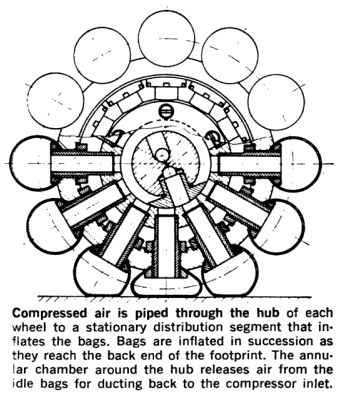

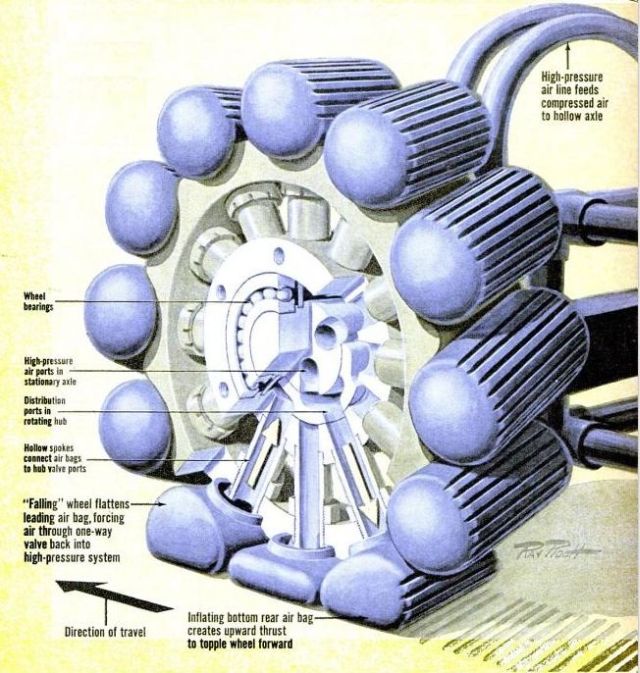

Mackerle simulates the action of a thrusting leg with an inflatable rubber bag, and uses a ring of these around the wheel circumference in place of a regular tire. Compressed air is piped through the hollow axle to a rotary valve in the wheel hub that feeds it to only one bag at a time-the one on the ground directly behind the vertical axis of the wheel.

Pressurized with air, this off-center bag pushers the wheel off balance, causing it to roll ahead by gravity. It now rests on the next soft bag around the rim, and that bag is then inflated to give the next thrust.

The cycle is repeated with each successive bag to maintain rotation, while air is released from each retreating one in turn.

Thus the wheel "leans" forward and is advanced by a series of steps. But unlike a walking man, it is free from the decelerating forces of swinging, knee-bending legs because the pushing "feet" move in a continuous circle.

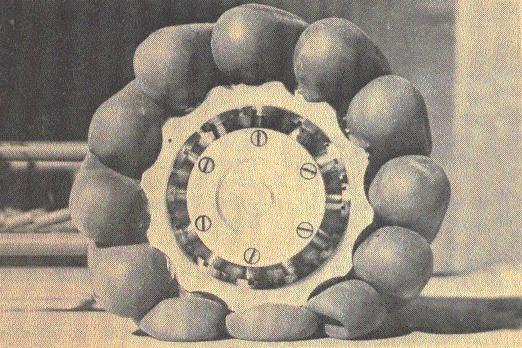

How the bags work. On the latest man-carrying Rotoped, the wheels are shod with a ring of 12 ball-like bags. Pitched 30 degrees apart, the bags are spaced out in a zigzag pattern so that they can be as large as possible for maximum ground-contact area to support the vehicle, and for maximum thrust under pressure to drive it.

Each wheel has an outside diameter of 20 inches, while the elastic bags are about 4 1/2 inches high. This height is the effective working stroke of the bags when inflated and, since it is done to half the wheel's radius, the kick behind the axle is pretty hefty.

The experimental vehicle is powered by a 26-hp, Trabant, (East German) minicar engine driving a Roots-type blower. The blower–taken from an old two-stroke GM diesel-puts out nearly 800 pounds of compressed air per hour at nine p.s.i. The chassis of the vehicle is a tubular framework that serves both as a pressure tank and to distribute air to the wheels.

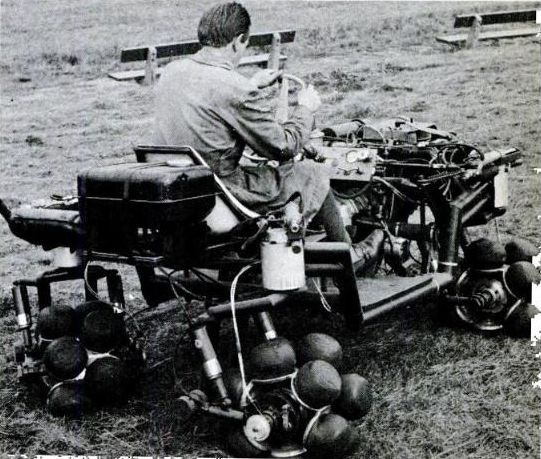

Routing the air. Air from the blower is piped via side members to the four corners of the chassis, and is then taken down through the suspension assemblies and enters the wheels through one side of the hub. The wheel hub contains a pivoted sleeve supported by bearings on the hollow stub axle. An eccentric on the stub axle has a port which, as it rotates, matches up with a series of ports in the sleeve. The sleeve ports feed directly into the individual air bags.

For maximum efficiency, the pneumatic transmission is a closed-circuit system, Compressed air released from the deflated bags is ducted out the other side of the wheel hubs and, through a different set of suspension and chassis tubes, back to the blower inlet for recirculation.

Speed is controlled by the conventional engine throttle, the the greater the pressure from the blower, the faster the bags are inflated. But thrust can also be varied by shifting the point at which air is injected into the bags. This is done by a rotary distributor valve in the hub of each wheel that can be turned so that air is fed to the underside bag at any angle between zero and 30 degrees in relation to the perpendicular.

Like shifting gears in an ordinary transmission, turning this valve changes the timing and hence the leverage acting on the wheel, altering its thrust to suit fast or slow travel or the climbing of gradients. In fact, the valve can be turned through a second 30-degree sector to direct the air to the other side of the perpendicular, providing reverse simply by inflating the bags ahead of, instead of behind, the axle.

On the Rotoped, the valves are operated by flexible cables and the four sets of these terminate at a drum operated by a control lever in the cockpit. The wheels are carried on horizontal suspension arms with airtight pivots, and strut-type motorcycle springs are used. There is four-wheel power steering, and each suspension assembly has a swivel pin in a sealed chamber with separate passages for the incoming and outgoing compressed air.

Power steering is necessary because of the width and the knobbly form of the wheels. Individual hydraulic servos for each wheel operate against the control arms. The control arms are mechanically linked together.

Absence of any drive shaft means complete steering freedom, and wheels can be angled through 180 degrees. So the tail tracks around behind the nose on a sharp turn, and you pivot in a circle with the wheel hard over. By resetting the air-distribution valves and their controls, the vehicle can be made to move perpendicularly, or crab-track its way along, in the manner of GM's variable-response vehicle ("Computer on Wheels," PS Aug. '69).

Mackerle's research vehicle at present has a top speed of 12 m.p.h. and can climb a 20-degree grade. But that's with worn blower and same air leaks in the chassis joints. A working pressure of 15 instead of nine pounds will be attainable with new equipment, and Mackerle figures performance would then be considerably better.

And for the future? Mackerle has his eye on more distant horizons for his revolutionary form of locomotion. He's thinking of a lunar vehicle. On the moon, the walking wheel would really shine.

While the moon's low gravity would reduce the friction-based adhesion of an ordinary wheel, the air bag one would keep driving regardless of the power applied. On the frequent bounces off the rocky ground (like the Kangaroo leaps of the astronauts on the Sea of Tranquility), the wheels wouldn't be spinning under power each time they returned to the lunar surface.

Absence of atmosphere on the moon means that less pressure would be needed to blow up the bags, as there is no external pressure to oppose inflation. Power requirements would thus be lower. And solar energy could possibly provide hot air directly for propulsion.

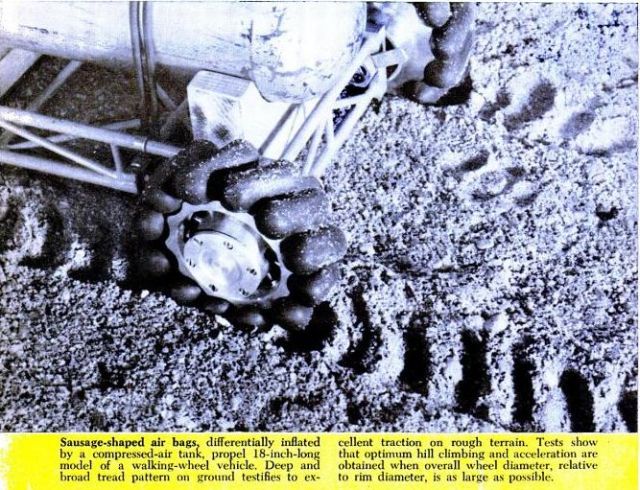

The above Rotoped was developed from the earlier version as reported in Popular Science July 1964.

This earlier version did not have the round bags but saugage-shaped bags, limiting its steering and versatility.

Source: Popular Science, July 1964 and Jan 1970.

A close-up of the sausage-shaped bags from the earlier wheel. Source: L'Auto Journal , Apr 1969 found here.

See other Walking Wheels at the bottom of the Walking Machines page.