Underwater power source

Publication number US3418818 A

Publication type Grant

Publication date 31 Dec 1968

Filing date 22 Apr 1966

Priority date 22 Apr 1966

Inventors Renic P Vincent, Lawrence B Wilder

Original Assignee Pan American Petroleum Corp

ABSTRACT OF THE DISCLOSURE A method and apparatus for supplying power to underwater apparatuses which makes use of the head of water at the depth of the apparatus to drive a hydraulic motor. A lower pressure container is provided to receive discharge water from the hydraulic motor. Means are further provided to rejuvenate the low pressure container.

This invention relates to apparatus for carrying out operations at underwater installations such, for example, as at an underwater wellhead, an underwater oil and gas producing facility or storage and the like. It relates particularly to a novel way of supplying power for such underwater apparatus.

The search for oil and gas has in recent years led to the drilling of many wells in water-covered areas. In fact, many of our more prolific oil and gas wells have been discovered in such marine locations. Many of the wells for the development of such fields may be drilled in water up to 600 feet or more in depth. These developments of offshore locations are resulting in the installation of large amounts of underwater equipment used in producing the oil and gas fields. Many of these installations are at depths below that at which divers can safely work. Therefore use has been made of what is known as an underwater manipulator in installing underwater equipment on the ocean floor for such wells or for carrying out workover operations underwater at any of the various ocean floor installations.

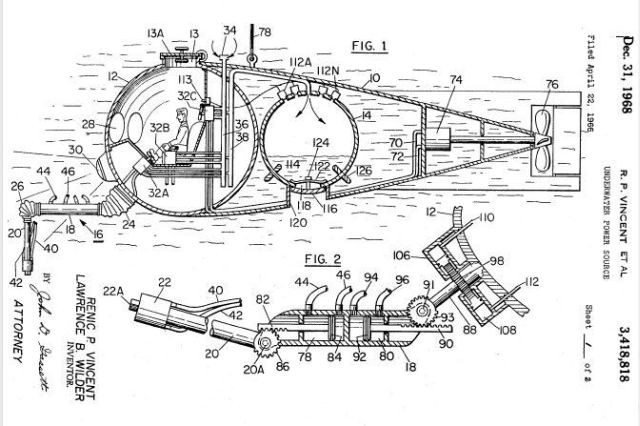

The manipulator may take various forms but usually includes a compartment maintained at near atmospheric pressure for the operator and is further provided with robot-like arms extending from the exterior of the compartment for performing various operations such as holding equipment, tightening or loosening bolts and the like. One such underwater manipulator is shown in US. Patent 3,165,899.

One of the major problems in the use of such underwater manipulators is that of providing an adequate power source for the various operations of the manipulator. Electrical storage batteries provide the most common means of power. However, these batteries add considerably to the bulk and weight as well as to the cost of such manipulators or vessels containing such manipulators.

It is an object of this invention to provide a novel means for supplying power for underwater manipulators.

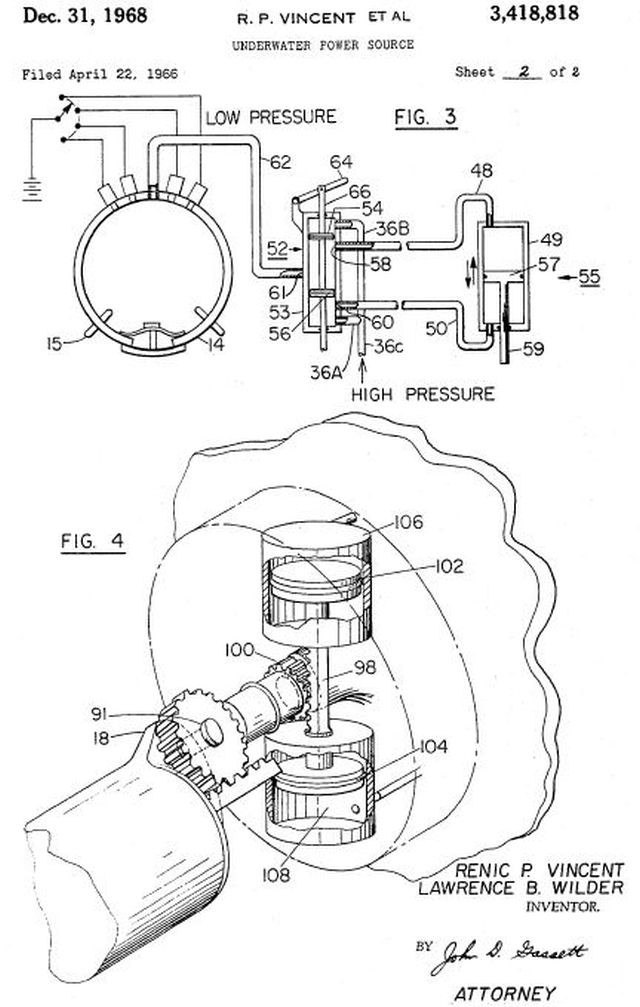

In a preferred embodiment, an underwater vehicle which has a body structure for supporting the manipulator arms is provided with a high strength container (in addition to the operators compartment) which is able to withstand great pressures. A hydraulic motor is supported by the vehicle. The high pressure side or inlet of the hydraulic motor is connected to the water exterior of the vehicle which is at a pressure dependent upon its depth. For example, at a depth of 600 feet, the exterior pressure approaches 275 p.s.i. The discharge side of the hydraulic motor is connected to the container which is at atmospheric pressure or at about 15 p.s.i. The differential pressure across the hydraulic motor then is well over 250 p.s.i. which is quite substantial. As power is needed, water 3,418,818 Patented Dec. 31, 1968 from exterior the vehicle is admitted to the hydraulic motor.

The discharged water from the hydraulic motor eventually fills the container to the point that the pressure within the container approaches that of the Water at the depth of the vehicle. When the container becomes filled with water, according to our invention, the system can be rejuvenated rather easily. We have provided check valve means in an outlet from the container to the water surrounding the vehicle. The cheok valve means can be held shut by a spring aided by the hydraulic force exterior of the container. Before the vessel descends, a slow burning propellant in a water-proof enclosure is placed within the container. A suitable propellant is identified as Amoco Chemical AGF which is an ammonium nitrate base with an asphaltic filler and commercially available from Amoco Chemical Corporation, Seymour, Indiana. When the container is filled with water, the propellant is ignited and will burn at a pressure higher than the ambient water pressure and at a temperature of about 3535 F. This pressure forces the water out through the check valve and in effect readily empties the container of water. At the moment the gas has forced the water out, the gas remaining in the container is at a pressure about equal to that of the surrounding water but at a temperature much higher. The check valve then closes. As the gas cools, the pressure in the container drops rather rapidly until it is well below the pressure of the surrounding water. Thus the container is ready to receive additional water from the discharge of the hydraulic motors and the system has in effect been rejuvenated.

See other early Underwater Robots here.