Underwater manipulator system

Publication number US3414136 A

Publication type Grant

Publication date 3 Dec 1968

Filing date 18 Jan 1966

Priority date 18 Jan 1966

Inventors John R Moore, James S Sweeney

Original Assignee North American Rockwell

ABSTRACT OF THE DISCLOSURE System for positioning an underwater manipulator arm to correspond with the position of an analog arm. The flow rate and pressure of the fluid transmitted to the hydraulic actuators used to move the manipulator arm are measured by transducers. The output of the transducers is integrated or otherwise processed by conversion circuits to produce a signal, indicative of the position of the manipulator, which signal is compared with another signal indicative of the analog arm position. An error signal thereby is produced which appropriately actuates valves controlling the fluid flow to the hydraulic actuators, thereby causing the manipulator arm to move to the desired position. Rate damping is provided to the analog arm to simulate the viscous damping experienced by the manipulator during motion in the viscous underwater medium.

This invention relates to an underwater manipulator system and more particularly to a system for controlling an underwater manipulator with an analog manipulator.

Conventional designs of underwater manipulator systems utilize bidirectional drive systems and binary control systems for the elements in the system. Visual observation is often relied on for position sensing. In more sophisticated control systems, optimal design utilizes controlled element position sensing. The position detector produces a signal proportional to the position of the device. From the detector signal and a reference signal, an error signal is produced to drive the controlled element. The lack of direct position sensing precludes precise control.

Control systems operated by simple binary switching to control position, velocity, etc. of a device tend to be difiicult to operate for accurate positioning.

Performance of a control loop composed of a simple drive system, large controlled element mass, lack of position sensing and transmission delay due to human reaction time is characterized by uncoordinated sequential manipulator movements, long action times and low precision.

Precision feedback by direct transducer sensing of the elements of the underwater manipulator is diflicult since the high pressure, corrosive undersea environment multiplies the problems of sealing the transducer and signal leads. Therefore, it is desirable to monitor the characteristics of the energy which actuates the elements of a manipulator.

The system of the present invention provides an improved control system which overcomes the deficiencies indicate dabove by measuring the characteristics of the actuating fluid, such as pressure and/or flow rate, to each manipulator element.

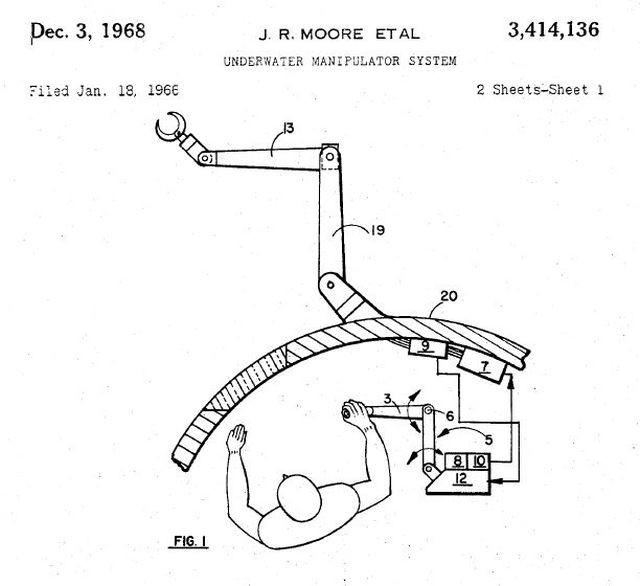

Briefly, the system comprises an analog arm of movable elements which may be positioned manually and an underwater manipulator of movable elements which is driven in accordance with signals generated by the analog arm to assume the same position. For example, if an element of the analog arm is positioned at a 45 angle with respect to a reference, the underwater arm element would be driven in synchronism to assume a 45 angle Patented Dec. 3, 1968 with respect to the reference. More specifically, the system utilizes a drive means which is responsive to the motion of an element of the analog arm and which provides a signal for driving an element of the underwater manipulator. Each element of the underwater manipulator includes a hydraulic position actuator which is driven by a fluid. Sensing means detects a corollary of the motion of each element of the underwater manipulator and generates a signal indicative of that motion. By knowing the initial position of the manipulator and the amount of motion, a new position can be determined if desired. The signal is generated by monitoring hydraulic fluid pressure and/or flow rate to a particular element being actuated. Each signal is compared by the drive means with a signal indicating the motion of an element of the analog arm. If they are different, an error signal is generated to drive the underwater arm until the amount of motion and therefore the signals are equal.

Each element of the analog arm includes sensing means and means for providing damping to approximate the natural damping of the underwater manipulator. Other features of the analog manipulator and arm are substantially the same except for size.

Although the analog arm may be positioned manually, in one embodiment, a computer monitored and controlled servo system is used. The terms arm and manipulator are interchangeable, although for clarity the analog portion is referred to as the arm and the external portion is referred to as a manipulator.

Therefore, it is an object of this invention to provide an underwater manipulator system having an improved positioning system.

It is another object of this invention to provide a system using anobservable analog device as a position reference for an underwater manipulator.

Another object of this invention is to provide a system reducing the visible detection required for the positioning of an underwater manipulator.

A still further object of this invention is to eliminate direct transducer sensing of the movablce elements of an underwater manipulator and to monitor the actuating hydraulic fluid characteristics for an indication of manipulator position.

A still further object of the invention is to provide rapid, accurate and coordinated manipulator control by measuring fluid pressure and/or flow rate to a manipulator element.

See other early Underwater Robots here.