1961 – Trieste Submersible with Manipulator Arm by Harold Froehlich – General Mills. Image source: Manned Submersibles, Frank Bushby, 1976. The Trieste was purchased by the U.S. Navy in 1958. Development of the manipulator arm, instigated by Don Walsh, was done by Harold "Bud" Froehlich of General Mills. Based on the Model 150 arm, it was finally commissioned in 1961.

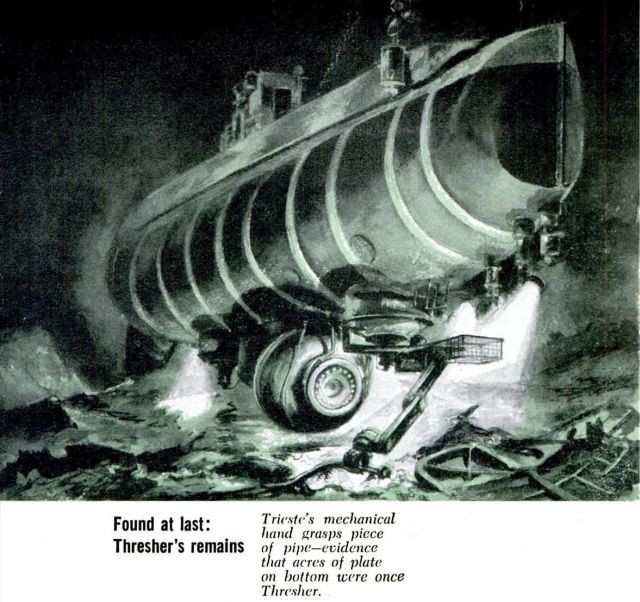

In 1963, Trieste was used to locate The USS Thresher which tragically broke up and sunk in deep waters earlier the same year. Top image from Popular Science, Feb 1964.

UNDERWATER MANIPULATORS

© 1966 American Society of Naval Engineers

Naval Engineers Journal

Volume 78, Issue 6, pages 1003–1009, December 1966

When Walsh and Piccard rode Trieste 35,800 ft. to the bottom of Challenger Deep in 1960, they proved that man could have access to any part of an unexplored area equal to 3/4 of the earth's surface. A dream cherished by man since Alexander the Great had become reality. But, as important as was the achievement of gaining access to the vast bottom of the sea, it was but a step in the conquest of the depths. To truly conquer this new frontier, man must be able not only to go there, but to travel over large areas and do useful work there. To provide a capability for doing mechanical work, a number of underwater vehicles have been equipped with mechanical manipulators, and more are planned or in progress.

TRIESTE

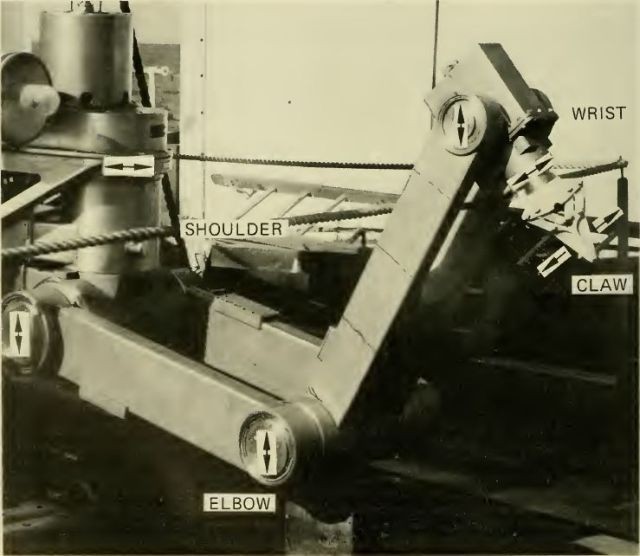

The first manipulator fitted to a manned deep submersible was the General Mills Model 150 manipulator purchased by the Navy for use on the original Trieste in 1961.

To provide a manipulator for scientific sampling and for performing other tasks at the bottom, the Navy turned to industry to draw on the knowledge accumulated over the previous two decades of nuclear hot-cell-manipulator-development.

The fully developed and proven General Mills 150 was modified for underwater use. With six motions and a capacity of 50 lb. at an outreach of about 30 in., the d-c electric-motor-driven Model 150 offered an attractive addition to the capabilities of Trieste. A mounting was provided, pivoted to the forward ballast shot tub, and equipped with a hoist which could lower the manipulator into operating position before the pilots view port and retract it out of the way when not in use. The shot tub was suspended from a magnetic release device and could be released from inside the pressure sphere.

This safety feature proved the undoing of the first manipulator. The release was inadvertently tripped shortly after installation, and the manipulator was lost before extensive data could be obtained. A second Model 150 manipulator procured for Trieste retained the aluminum-magnesium structural material used in the hot-cell version. Because of the size and nature of Trieste, it remained in the water for relatively long periods of time, making the manipulator inaccessible for maintenance. Long immersion led to corrosion of the fastenings and castings. Corrosion developed at any point where the surface got scraped, and developed around fastenings as a result of gradual soaking of seawater through the paint film. (more but not available at time of publishing)

The General Mills Model 150 Manipulator Arm

The General Mills' Model 150 Manipulator. See also General Mills technology described here.

Harold "Bud" Froehlich

The dream of building a manned deep ocean research submersible first started to move toward reality on February 29, 1956. Allyn Vine of Woods Hole Oceanographic Institution (WHOI) attended a symposium in Washington, where participants drafted a resolution that the U.S. develop a national program for manned undersea vehicles. From this beginning the community eventually obtained the Trieste bathyscaphe, but it was quite large and not very maneuverable – a better craft was needed.

In 1960, Charles Momsen, head of the Office of Naval Research (ONR), petitioned for scientists to rent a submersible with ONR funds, and found WHOI investigators interested. In the spring of 1962, after unsuccessful negotiations with various submersible builders to rent a sub, Vine and others at Woods Hole went and requested bids to buy a small submersible based on drawings made by Bud Froehlich for a vehicle he called the Seapup. General Mills won the bid for $472,517 for an unnamed 6,000-foot submersible. Source: here.

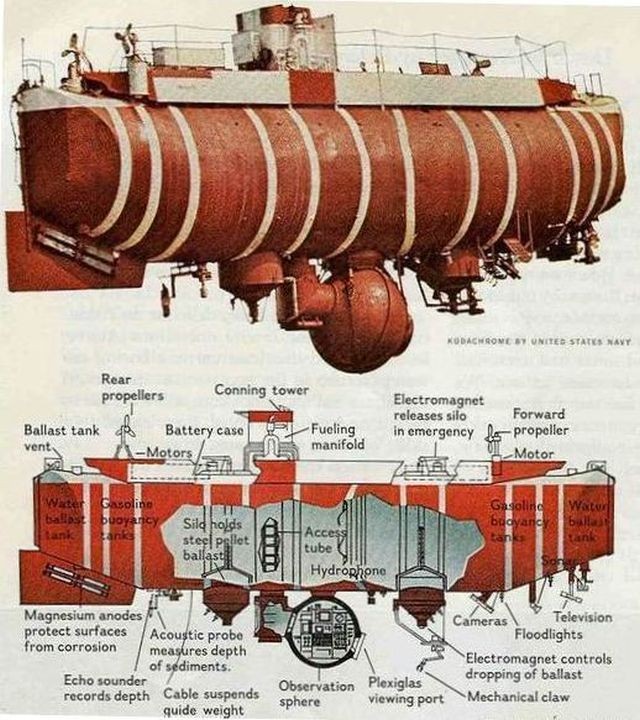

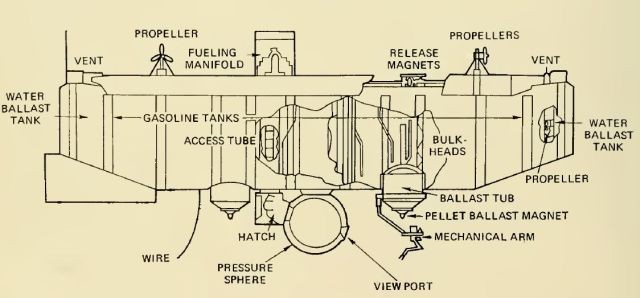

BRIEF TRIESTE HISTORY

Trieste consisted of a float chamber filled with gasoline (petrol) for buoyancy, with a separate pressure sphere to hold the crew. This configuration (dubbed a bathyscaphe by the Piccards), allowed for a free dive, rather than the previous bathysphere designs in which a sphere was lowered to depth and raised again to the surface by a cable attached to a ship.

Trieste was designed by the Swiss scientist Auguste Piccard and originally built in Italy. His pressure sphere, composed of two sections, was built by the company Acciaierie Terni. The upper part was manufactured by the company Cantieri Riuniti dell'Adriatico, in the Free Territory of Trieste (on the border between Italy and Yugoslavia); hence the name chosen for the bathyscaphe. The installation of the pressure sphere was done in the Cantiere navale di Castellammare di Stabia, near Naples. Trieste was launched on 26 August 1953 into the Mediterranean Sea. The design was based on previous experience with the bathyscaphe FNRS-2. Trieste was operated by the French Navy. After several years of operation in the Mediterranean Sea, the Trieste was purchased by the United States Navy in 1958.

The Navy bought the Trieste from the men who had built it in 1953, Auguste Piccard and his son Jacques, for $250,000. It was actually the second Trieste; the original 1948 model hadn't held up well. Source: Wikipedia.

See other early Underwater Robots here.