Android Space Manipulator

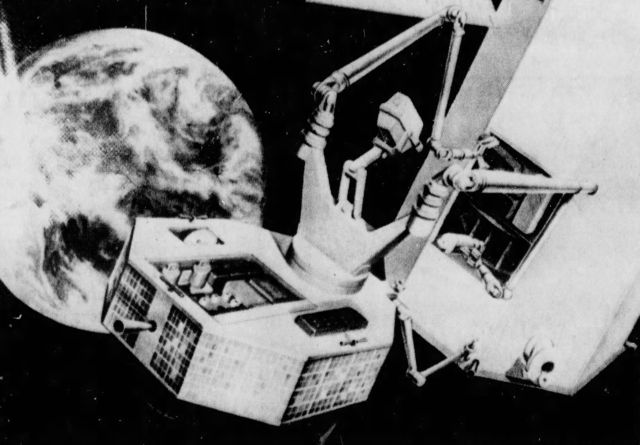

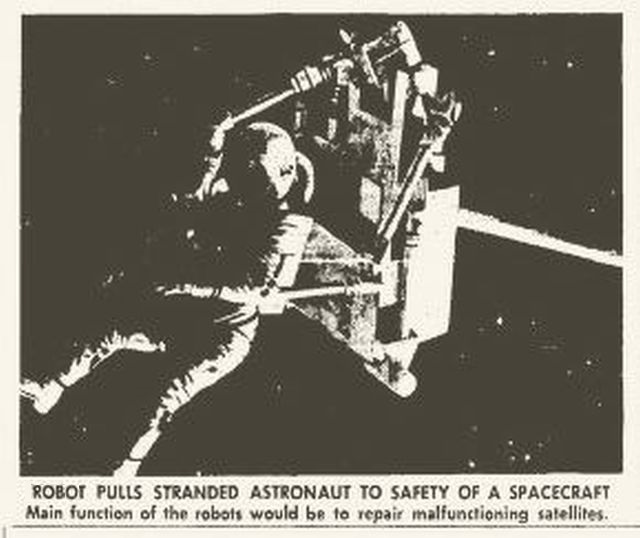

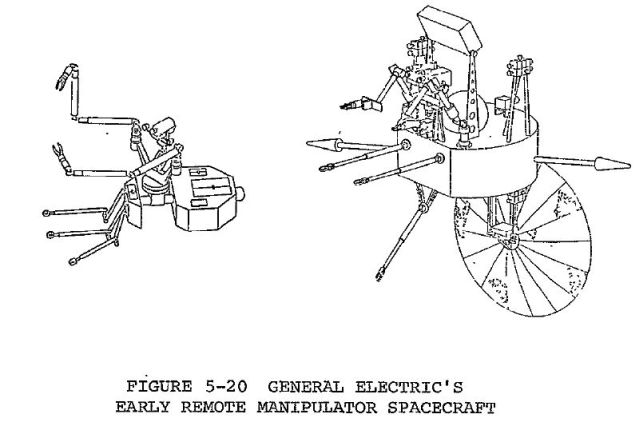

Robots May Tend Ailing Satellites -One of the frustrations of scientists is "burned out" satellites, those which, because of a malfunction or a worn-out part, inertly orbit the earth, doing no worldly good. "Such a satellite becomes a million dollar bit of space debris for lack of a two-dollar part. It would be impractical if not impossible in most cases to send an astronaut to do the job and in the few cases, where practical, the expense would be prohibitive. The answer would seem to be a highly sophisticated robot space vehicle which could be manipulated by ground control. A National Aeronautics Space Administration contract to make design studies of such a "space repairman" has been awarded to the General Electric Space Systems Valley Forge, Pa. In its ARMS (Application of Remote Manipulators in Space) project, GE scientists envision an orbiting space complex consisting of tender (home base) satellite and one or more robot repairmen [text illegibie].

This complex could easily be put into a continuous 24-hour orbit by a booster such as a Titan III-C. The tender would be controlled by radio from a ground station, receiving instructions and navigational information on satellites requiring repair. Before the rendezvous with the disabled satellite, however, the tender and its resting repairman would have to make a linkup with a repair kit, containing replacement parts or modules, launched into orbit from the earth. After this docking the tender, repairman and repair, all joined in one complex, would change orbit to close on the satellite needing repair. The intricate maneuvering required to complete this rendezvous in the vastness of space and the ensuing repair job would be directed from earth. This is made possible by "eyes" in the space units. The tender would be equipped with at least one television camera and the robot repairman would have one or, more probably, two. The direction and focus of the cameras could be adjusted from earth. The robot repairman is a box-like creature with three multi-jointed arms and pincer-like fingers that can be operated by remote control. In addition to the information supplied by the TV camera, the manipulators will also feed information, much like human muscles and limbs when performing a job. This enables the ground-control station to make adjustments to properly conduct the repair. The repairman will be maneuvered by miniature attitude control rocket nozzles which can be operated from earth. Present space vehicles are not designed for such easy repair. Satellites of the future would be designed so that trouble-prone, sensitive or exhaustible parts would be located on the outer surface in easily replaceable modules. GE studies indicate that the ARMS project would pay off after 12 satellite repairs, another way of saying that the costs of the repair system would equal the replacement cost of 12 non-functional satellites and any succeeding repairs would be pure gain for the space system. And, of course, should one of the repairmen develop a malfunction, he will be operated on by another robot.

Source: Oakland Tribune (Newspaper) – September 15, 1968, Oakland, California

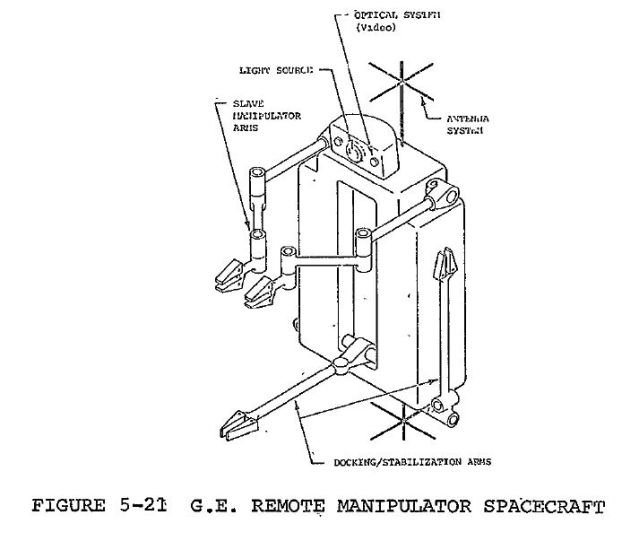

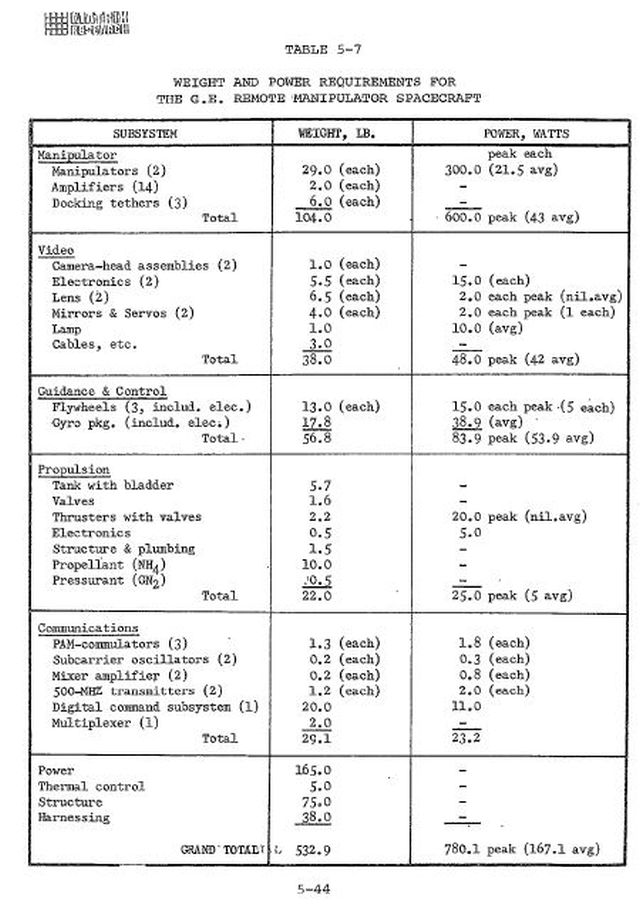

The spacecraft has an approximate weight of 530 pounds and is approximately 12 inches deep by 40 inches wide by 75 inches high (including antennas). It has two electric bilateral manipulator arms that are slave to a master control system in a remote site. The system has a payload capability of about 500 pounds and a mission duration of 10 hours (Interim – Kugath, 1969).

Subsystem Description

Translation Subsystem

The propulsion is accomplished by a common blow-down monopropellant hydrazine subsystem. It would have large rendezvous engines for translation to the worksite and smaller thrusters for attitude control and maneuvering.

Stabilization/Control Subsystems

The attitude-control subsystem functions in two modes, 1) it stabilizes only the remote manipulator spacecraft; and, 2) it also stabilizes the worksite by a three-axis, rate-integrating gyro package. A momentum storage device reduces the thruster usage at the worksite.

The spacecraft maneuvers are performed automatically; the inputs to the guidance computer are produced by (docked satellite). The attitude reference is supplied.

The optical (video) system consists of two cameras which

1) give the operator a three-dimensional display,

2) provide redundancy in case of a camera failure, and

3) serve as range finder to supply data to guidance/control subsystem for rendezvous and docking.

Actuator Subsystem

This subsystem consists of three docking/stabilization arms and two manipulator arms. The manipulators are bilateral, slave type that resemble the human arms but

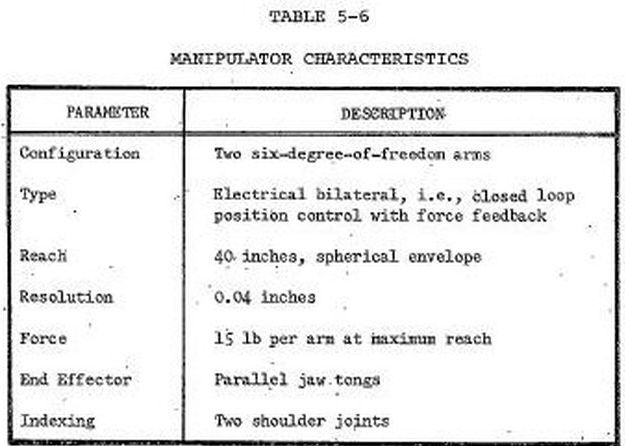

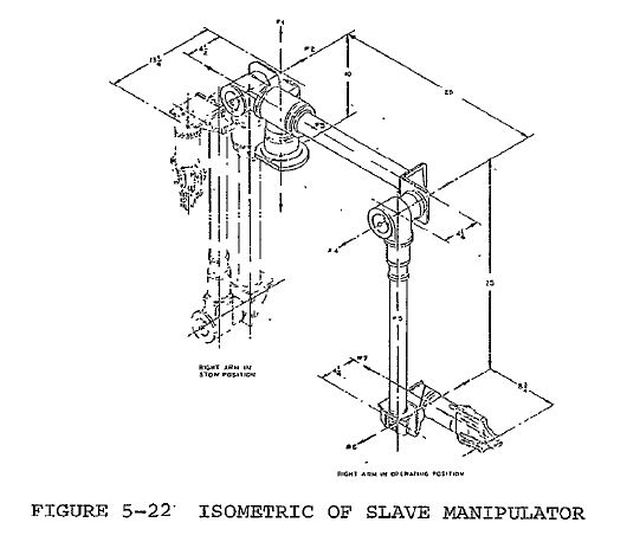

are not anthropomorphous. The manipulator characteristics are shown 'in Table 5-6 and dimensions are given in figure 5-22. Table 5-7 gives the weights and estimated power requirements for the remote manipulator spacecraft.

Source: SELECTION OF SYSTEMS TO PERFORM EXTRAVEHICULAR ACTIVITIES Man and Manipulator Contract # NA88-24384

Volume 2, Final Report – Prepared for Marshall Space Flight Center – 9 April 1970.

Footnote: August, 2014 – This 1968 GE concept is the closest that resembles the Robonaut R2. The Robonaut R2 is currently the only humanoid robot in space and was delivered to the International Space Station in 2011. The current version can only operate internally, though. There is an earlier dextrous dual-arm robot, called Dextre, delivered to the ISS in 2008, but this is not humanoid in shape and size.

Robonaut R2 shaking the hand of Station Commander, Dan Burbank.

See other early Space Teleoperators here.

See other early Lunar and Space Robots here.