see full pdf here.

Personal Computing FEBRUARY 1978 p56-61

BERT (excerpt)

Building Your BASIC Robot

Robots vary in sophistication and control structure, from Mars-walking space probes and industrial assembly robots to self-motivating household pets and computer-controlled "turtle" drawing robots.

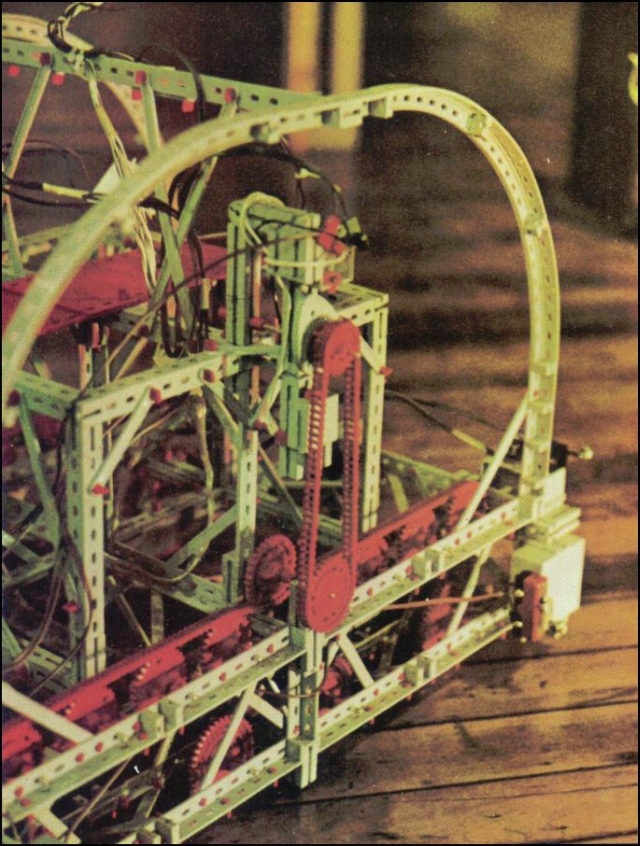

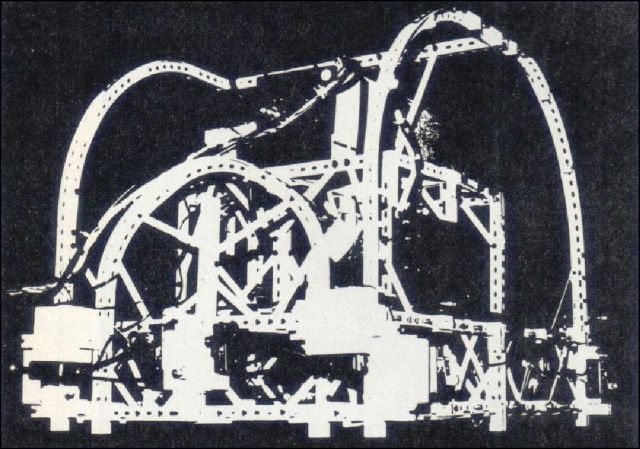

My interest in these simple mobile computer input-output devices, robots, led me to construct my own "mechanical pet", Bert. Bert can move forward or backward, and pivot in either direction. Through a separate computer-controlled monitoring system, he responds to a pre-programmed direction after bumping into something and records his steps on film through a mounted video camera. A distance sensor controlled by the same computer keeps track of the distance he travels and guides him on a pre-programmed path.

Bert stops on command for any set length of time, and on command resumes his program where he left off. My reason for building this "robot" was, from the beginning, to construct a peripheral for my SWPC 6800 computer. My goal has been achieved —Bert is controlled entirely by SWPC 8K BASIC, version 2.0 And although there are speed limitations with BASIC, careful programming and reasonable compromise allow for the convenience of BASIC real-time control.

Bert is constructed almost totally of replaceable, interchangeable plastic parts manufactured by the fischertechnik Company of West Germany. Although expensive, the building material allows for quick translation of ideas into physical reality, and easy modification of an existing design.

Struts of various sizes, nylon/plastic equivalents of I-beams, rivets which attach struts to I-beams or other struts, plastic chain, gears, metal axles, cotter pins, motors with reduction gears and worm gears make up the building materials. Flexible skin-like material can also be attached to I-beams with rivets.

These materials result in structures that are light but strong. Bert can move 50 lbs. with only minor reduction in speed — Bert only weighs about 10 lbs.

Eight parallel fischertechnik low-voltage motors drive the robot (4 motors drive each of the two tracks). The motors are driven by regulated adjustable power supplies. The power now in use travels to Bert via cables at about 1.5 amps per side at 12 volts. A third power supply drives the CRC express serial relay interface and delivers .5 amps at 5 volts…….